Manufacturing technology to “drive the emerging circular economy” receives further backing

Recycling technology developed at University of NSW and turning waste into boutique building products has received a boost to its commercialisation, sharing in $5 million awarded to the first round of winners in the NSW Physical Sciences Fund.

The five winners were announced on Tuesday November 10, and included a manufacturer of 25 kilogram long-range carbon fibre “powered lift drones”, magnetic resonance analysers for ore, and UNSW Centre for Sustainable Materials Research and Technology (SMaRT Centre.) According to the office of NSW Chief Scientist & Engineer 60 applications were made for the inaugural fund.

SMaRT is developing “microrecycling” science to produce – among other things – glass panel building products, which “are made from a variety of waste materials including waste glass, single use coffee cups, used coffee grounds and waste textiles. Each panel contains between 50 and 80 per cent waste material, with many of these materials being diverted from landfill.”

Founding director of the centre Professor Veena Sahajwalla said that the funding would progress commercialisation of current work.

“We’ve developed manufacturing technology and capability so waste can be reformed into value-added materials and products, and kept out of landfill,” she said in a statement.

“Environmental benefits aside, this scientifically developed technology will help to drive the emerging circular economy, create jobs and enhance social and economic outcomes, not just for local communities but more broadly for the nation.”

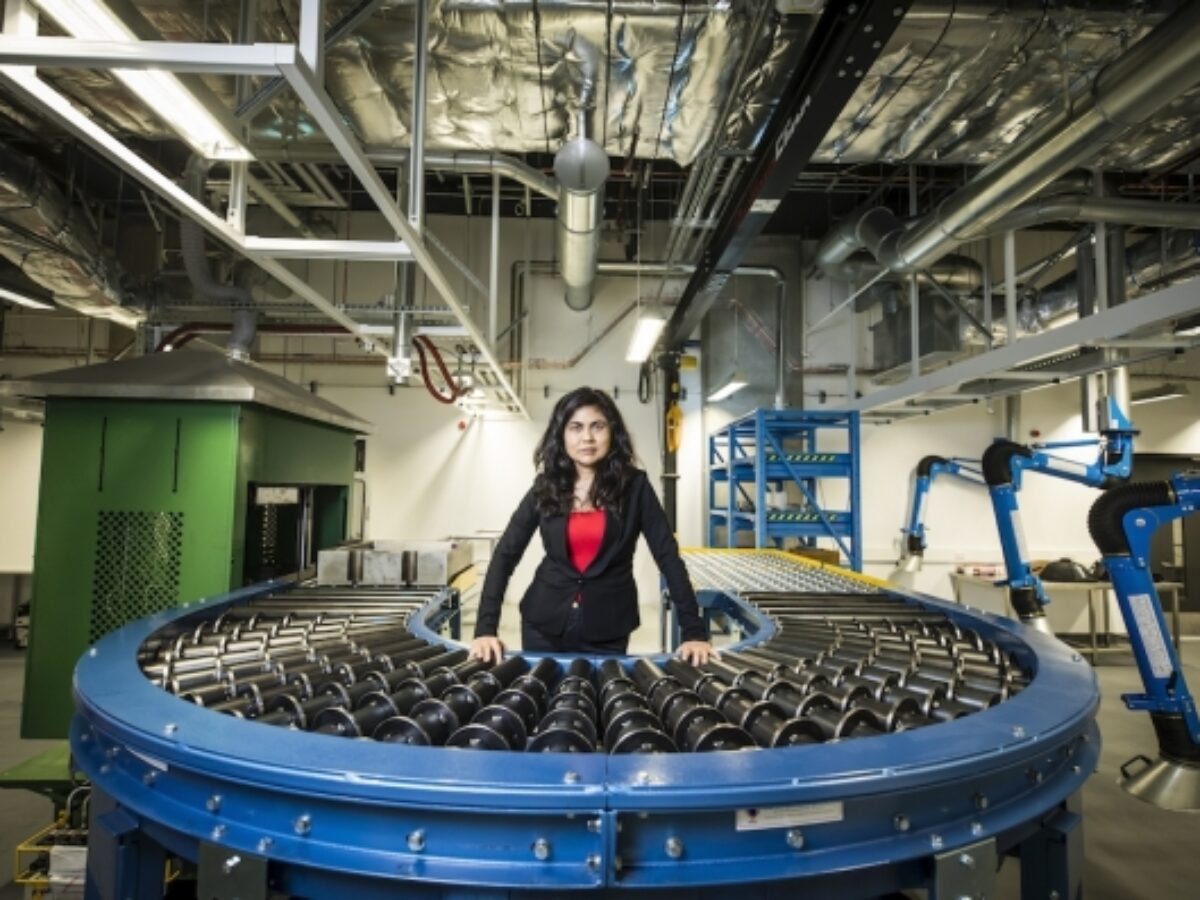

A commercial-scale “microfactory” at UNSW for modular, scaleable production from reclaimed materials, was launched in September by federal environment minister Sussan Ley.

Picture: Veena Sahajwalla in a section of the Microfactory (Anna Kucera)

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos