New atom-thin cathode coating could lengthen LIB lifespan: UQ

Researchers from the University of Queensland have developed a new process for coating a cathode, published in the journal Nature Communications, which they say could more than double the durability of lithium ion batteries.

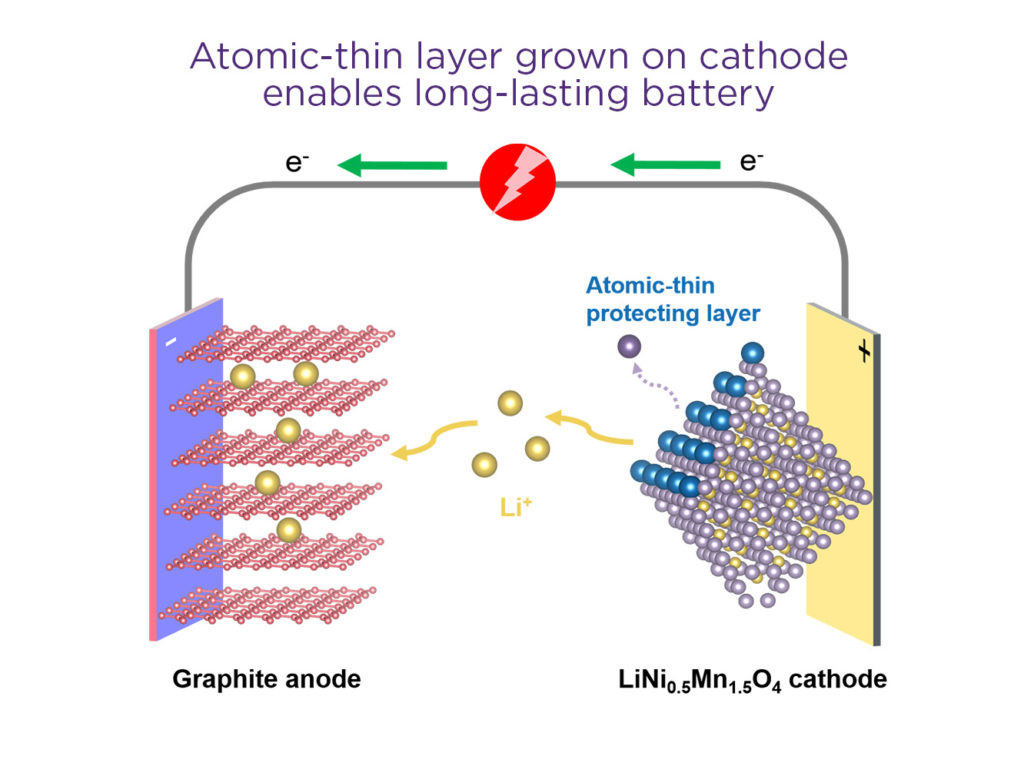

The team from the university’s Australian Institute for Bioengineering and Nanotechnology (AIBN) had developed a “uniquely-grown atomic-thin functional layer” for cathodes, said Professor Professor Lianzhou Wang (pictured) in a statement.

Wang’s team has demonstrated a battery that retained stability over 1,000 charge/discharge cycles, and he believes their research could improve the lifespan of batteries in everything from power tools to electric vehicles.

“This new approach features a minimal protective coating at a scalable process, paving the way for the deployment of these abundant high-voltage materials for next generation high energy batteries,” said Wang.

VSPC’s technical specialist Dr Rosalind Gummow said the process could be useful in stabilising other cathode materials which degraded through cycling.

“New methods like the use of epitaxial surface layers to improve the cycling efficiency and cycle life of high-voltage cathodes are vital in the quest to improve the energy density of Li-ion batteries,” said Gummow, whose company – a subsidiary of Lithium Australia – has won grant support from the Advanced Manufacturing Growth Centre to manufacture lithium ferro phosphate cathode material from recycled material.

The UQ team’s work, titled “Epitaxial growth of an atom-thin layer on a LiNi0.5Mn1.5O4 cathode for stable Li-ion battery cycling” and published last week, can be accessed here.

Pictures: University of Queensland

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos