New magnetic polymer made from recycled waste

A new multi-functional material which can be used to purify water, as a recyclable construction material, and as a lightweight machine component can also be moved remotely by a magnet.

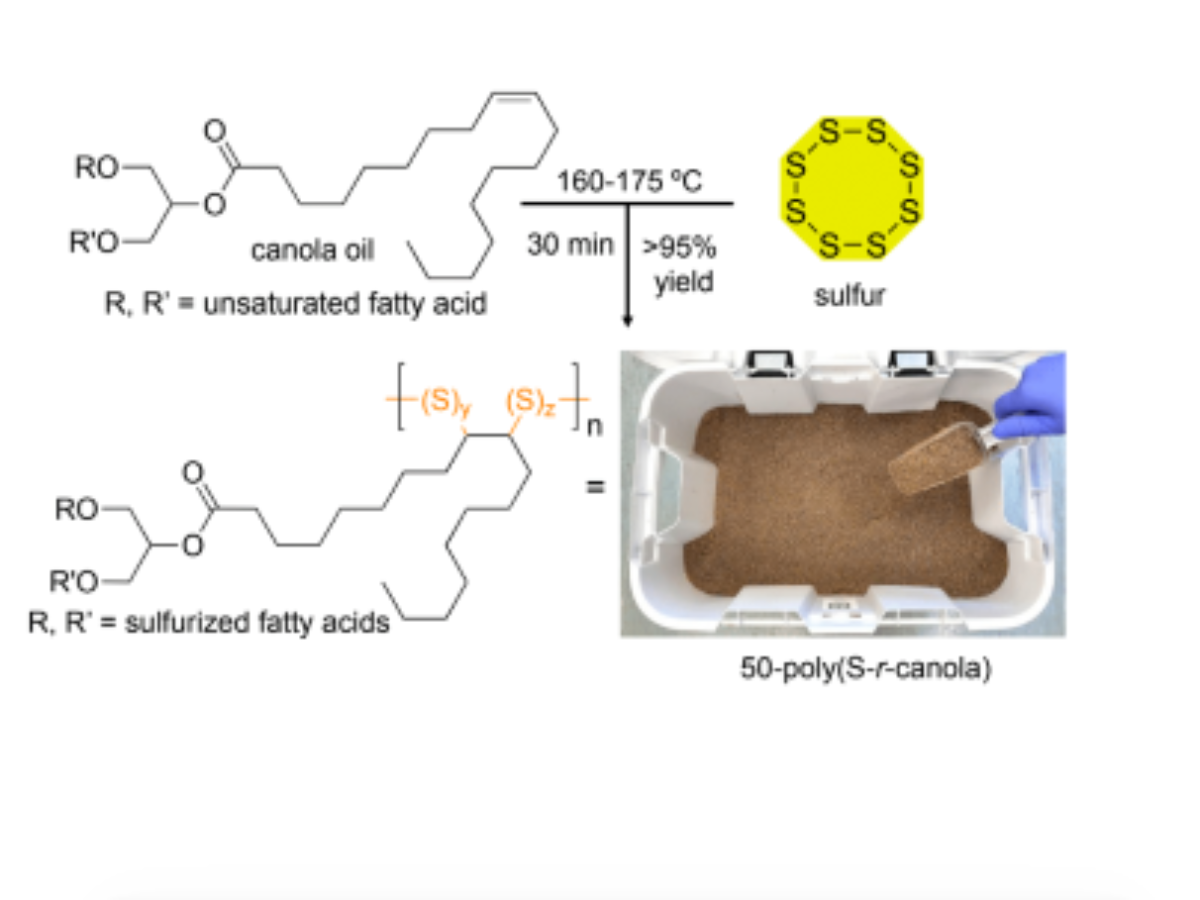

The new material that has been created and tested in the Chalker Research Lab at Flinders University, is made from magnetic iron particles and a sulfur-rich polymer, which combines elemental sulfur and an unsaturated plant oil, such as canola oil.

A mixture of these substances is hot-pressed to make the newly discovered material, with the iron particles imparting the ability to move the material with a magnet.

The iron also allows the material to be heated very rapidly with microwaves, enabling curing into a desired solid shape within seconds.

The new material is also recyclable, as it can be ground up and re-shaped multiple times.

Described in the study – Magnetic responsive composites made from a sulfur-rich polymer by Nicholas Lundquist, Yanting Yin, Maximilian Mann, Samuel Tonkin, Ashley Slattery, Gunther Andersson, Christopher Gibson and Justin Chalker – has been published in the journal Polymer Chemistry.

According to Flinders University the publication marks a significant development from the team in the Chalker Research Lab, which continues to new molecules and materials.

Lead author and Flinders University PhD Dr Nic Lundquist explains that the research team used the magnetic composite material to bind mercury in mine tailings, then retrieving the material with a magnet.

Dr Lundquist said: “This is a simple way to remove toxic metals from complex mixtures.”

Matthew Flinders Professor of Chemistry Justin Chalker says the new research provides important additional evidence of the potential and versatility of sulfur-rich polymers.

“This study illustrates the expanding utility and reach of sulfur-rich polymers.

“Heavy metal remediation, novel construction materials and light-weight and recyclable machine components were all made from this single, versatile material.”

Picture: Flinders University

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos