On-demand manufacturing: The perfect way to minimise your risk

ADVERTISING FEATURE

By RapidDirect

A lot of businesses have benefited from traditional manufacturing techniques. These businesses discovered that they could produce parts in large quantities so they won’t have to stress whenever a customer demands and needs them. However, acquiring a quote can be quite challenging when a company needs a custom product. The engineer or buyer communicates with different suppliers to get answers to various productions and quotes. Aside from that, they will still spend a lot of time negotiating prices with the manufacturer.

The entire process takes a lot of human resources and time. However, the manufacturing procedure lacks the honesty the companies need and want. When small and medium nuisances start-ups go through this procedure, they most likely diverge from the innovation part. Fortunately, companies do not have to take this route. With the assistance of on-demand manufacturing, also known as cloud manufacturing, companies can find the product parts they need and stay truthful to their business goals.

What Is On-Demand Manufacturing?

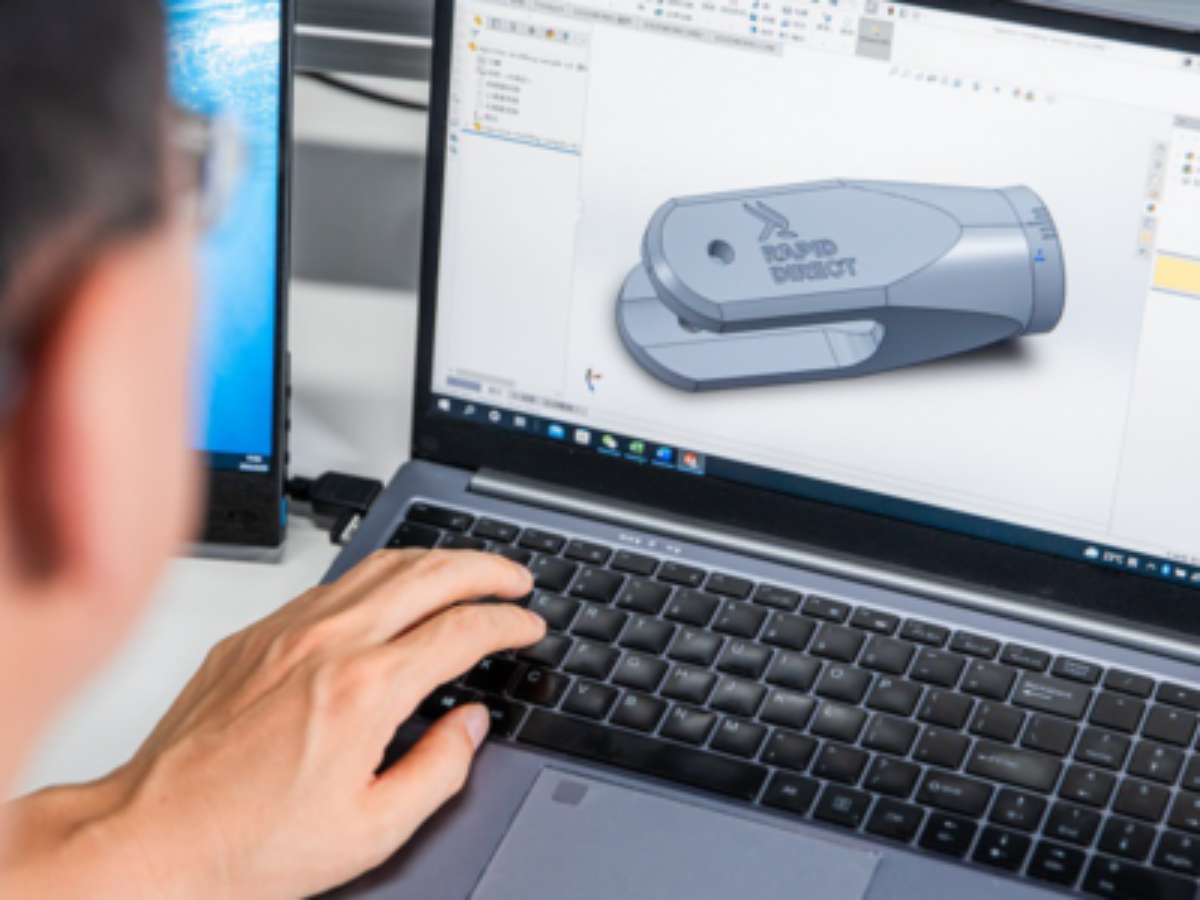

On-demand manufacturing is a new form of business that makes it possible for companies to provide support for the manufacturing from prototypes through the last stage of delivery to customers. Right now, more and more on-demand manufacturing companies deliver services with the use of a cloud-based software platform, making it easy for companies to get instant quotes, track inventory from any browser, and manage projects anytime.

For a better understanding, it is worth explaining the traditional manufacturing processes which on-demand manufacturing replaces. Before now, product designers had to learn how to operate inside a production system designed to meet large corporations' demands. This model has extremely high minimum order quantities (or expensive penalties for small orders) and long lead times, and most manufacturers are located overseas. Quotes are delivered via email or telephone in this model.

With on-demand manufacturing, only the goods needed at a given time are produced. Companies can request over a thousand copies of one part. This allows any company to supply their customers with the right product at a path jam time. SMEs and startups believe that an on-demand manufacturing service is the best solution they need to grow and expand their business.

How On-Demand Manufacturing Minimises Your Risk

On-demand manufacturing can help your company reduce risk through the following:

Customisation

Customisation options increase with on-demand manufacturing as businesses find it easy to make short-run production. Customisation helps increase a company’s sales conversions. More importantly, companies can make prototypes at a very low rate. Prototypes are always expensive to manufacture when traditional manufacturing methods are used.

Time to market

The traditional manufacturing method leads to a longer time between the quote and production. By the time a product gets to the market, the demand could have reduced. SMEs and startups might see this as a big issue. They project significant sales for a product, only to discover that substantial quantities of money are invested in non-moving goods. A company can serve more clients and make more money with faster manufacturing techniques without taking this risk.

Cost

The estimation process takes less time and the cost assessment time is lower with on-demand manufacturing. There is a rapid lead time due to the fast production. Most businesses find this appealing because it lowers the risk of their sale. They don’t have to place a required amount of orders to work with suppliers, thereby saving money and time.

Storage costs and inventory reduce drastically whenever a company uses on-demand manufacturing. Startups and SMEs need to reduce their cash flow, and on-demand manufacturing makes this possible. They pay less for warehouse fees and storage and require less labour. The money saved can also be used for other things like marketing.

On-demand manufacturing vs traditional manufacturing

The product designer and manufacturer determine the typical manufacturing pattern in traditional manufacturing methods. Product designers frequently collaborate with distant manufacturers on production, which depends on strong demand and the successful implementation of long-term plans.

On the other hand, on-demand manufacturing promotes better interaction and support between customers and producers throughout the production process. It starts with the prototype production phase and continues through the final stage.

On-demand manufacturing is quite cheap compared to traditional manufacturing methods. In traditional manufacturing methods, you have to order a minimum amount of goods, which might be quite expensive. However, in on-demand manufacturing, you can order any amount of goods depending on your choice.

On-demand manufacturing uses the flexibility of an online service and a cloud-based technological tool to create responses and manufacturing success. It offers the customer's order and delivers it at the right time. On the other hand, traditional manufacturing depends on the manufacturer and product designer. It results in higher demand and an increased production time.

On-demand manufacturing startups are more friendly than traditional manufacturing methods. Startups need just a few orders, which only on-demand manufacturers can offer. The traditional manufacturing method is expensive and time-consuming, and it's not friendly for startups.

How to choose an on-demand manufacturing service

Manufacturers use modern technology to increase their speed and accuracy. These are some of the on-demand manufacturing services and how to choose them:

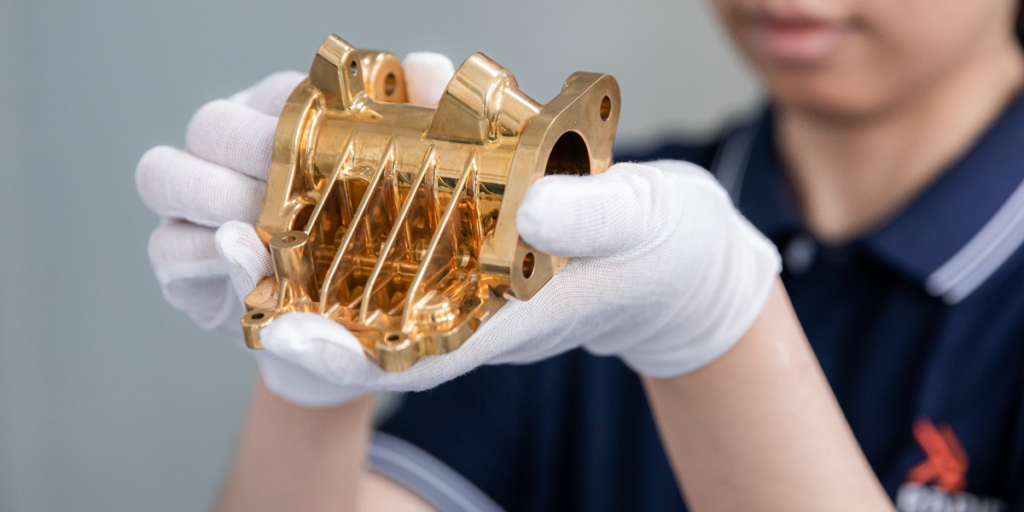

CNC Machining

Manufacturers use modern technology to increase their speed and accuracy. Computer Numerical Control machining (CNC) is one of those technologies. CNC machining helps you shape large chunks of materials into a more precise shape by using specific tools. However, there are some things to note before choosing who offers you CNC machining services.

Go for the company that offers CNC machining at an affordable price. The company also has to be reputable and have proper certifications. One thing you should also consider is the geographical location of the company.

Go for the company that offers CNC machining at an affordable price. The company also has to be reputable and have proper certifications. One thing you should also consider is the geographical location of the company.

Injection moulding

On-demand manufacturing can be very complicated if you choose the wrong partner for injection moulding. The first thing is to have a basic knowledge of the plastic injection process. The next thing is to check if the partner can offer a large volume of products and will comply with your specifications. Lastly, go for a company that is well efficient and capable.

Sheet Metal Fabrication

Sheet metal fabrication is an excellent way to give your design an artistic flair. So even if you decide to hire a fabricator, how do you know who to trust? Look for a company with a good name, check their equipment, see the kind of materials they have, and check for their customers' records.

3D printing

The last on-demand manufacturing service is 3D printing. Choosing a good 3D printing company is not so hard. All you have to do is to compare costs, check for their past projects and ensure they produce quality.

Conclusion

Traditional manufacturing methods might still be the foundation for primary manufacturing needs. However, the demand for on-demand manufacturing is rapidly increasing. On-demand manufacturing is rapidly transforming the manufacturing sector, accelerating innovation, and making it more accessible to both individuals and businesses.

Pictures: supplied

RapidDirect is a leading on-demand manufacturing platform for making prototyping and low-volume manufacturing more accessible. They developed a software-driven platform that gives customers access to cost-effective instant quotes, automated DfM analysis, bulk price comparing, all-in-one-place order management, and transparent manufacturing process.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos