Reframing the construction waste issue

For the latest nominee profile in our Australia’s 50 most innovative manufacturers campaign, we look at XFrame, a New Zealand-born company with a Meccano-like approach to construction. Brent Balinski spoke to the company’s CFO Simon McKean about building industry circularity.

The amount of material used and created by the construction and demolition sector is huge: 27 million tonnes — or 44 per cent of all managed waste in Australia for 2018-19, and the single largest source. 24 per cent of it was unrecycled.

Estimates include that it’s responsible for half of all virgin material used globally at the beginning of the lifecycle. At the other end, it produces about a third of all waste.

Ged Finch, then a Master’s architectural student in Wellington, New Zealand, began addressing he issue in 2017.

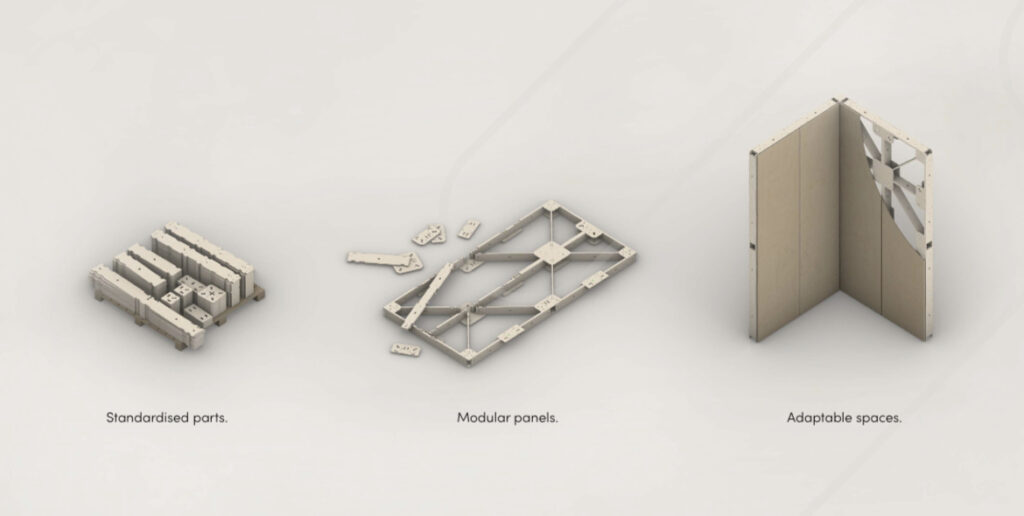

His concept was a timber framing system, able to be clipped together, then disassembled and reused when needed.

The resulting company, XFrame, has been operating commercially for three years, with a presence in New Zealand, the Tonsley Innovation District in Adelaide, and the United States.

Among Australian installations, they’re in the middle of their 20th at an ANZ branch.

The company has evolved Finch’s invention into software that can turn CAD drawings (or, they say, those on napkins) into CNC instructions to turn engineered plywood into components, a “95 per cent automated” tender, a calculation of carbon emissions, and assembly instructions.

Want to join @AuManufacturing’s list of Australia’s 50 most innovative manufacturers – apply to be recognised in this exclusive group here.

There is a standardised set of 12 components, able to be joined together with a rubber mallet and without glue or nails, then disassembled for reuse.

You might have just thought of Meccano. CFO Simon McKean makes the same comparison.

“We are, in Australia and New Zealand anyway, a technology company. We do bid for projects and we win projects on our own merits, but we want to be very much an outsourcing model,” McKean tells @AuManufacturing.

“The requirement for us to own CNC routers to run our sheet supply through, or extra staff or… install teams: we can very much outsource that aspect. So we want to stay quite lean in terms of what we offer.”

For a company focussed on sustainability – as well as creating systems and providing a platform to drive change in its industry – being able to have their products made close to the point of use makes sense.

For a company focussed on sustainability – as well as creating systems and providing a platform to drive change in its industry – being able to have their products made close to the point of use makes sense.

Within Australia, production of pre-assembled parts is handled by disability employer Bedford Group.

The vision is to have other companies join their quest for building circularity by creating XFrame-compatible products such as lining, insulation and cladding.

The three families of jobs handled are fitout, furniture and construction, with commercial fitouts generating the most demand so far.

McKean believes there is enormous potential in construction, particularly housing, due to the well-documented supply pressures. He mentions roof trusses as a current area of R&D to this end.

“So we’re working on at the moment a sort of a final set of instructions really that we can XFrame housing projects. So we know we can do the walls very, very comfortably,” he explains.

“And whilst we can do flat roofs, what we want to work out is roof trusses. So we’re going through a lot of analysis there on the automation and certification of roof trusses so that when we do go to market with a housing alternative, we’ve got a complete package ready for people.”

Of course, the company is also aiming to improve everywhere else.

As with solar energy enterprise 5B – another company describing itself as in the platform game – its focus is not on production in-house, though being able to prototype is very important for understanding the challenges faced by users.

“So how do we keep innovating? We’ve got a great tech platform, we’ll keep refining that. So our innovations are how we put a sheet of plywood through the CNC and [it’s under] 3 per cent waste. Can we make that 1 per cent or 0 per cent?” says McKean

“Some of our innovation is what method do we use to stack, maybe, a container where something goes to site? What’s the most efficient way at the other end to unload? How do we try to improve every aspect for saving money for us and the client, but also speed of installation? So we really think hard about innovation at as many levels as we can.”

In this episode of @AuManufacturing Conversations With Brent Balinski, McKean tells us about the company’s story so far, distributed production, looking towards large-scale residential projects, and more.

Episode guide

1:18 – The background. Five years in.

3:10 – Clients so far. Almost 20 installations at ANZ bank sites in Australia. Presence at Tonsley in Adelaide and New Zealand where the company was founded.

4:30 – The problem – construction industry waste – that inspired PhD student Ged Finch to develop XFrame.

7:05 – The outsourcing model and how it works. Partnership with Bedford Group.

8:30 – International customers.

11:14 – Going from drawing to tender. Plus the bits that aren’t automated in this.

13:10 – Construction, fitouts and furniture. The current work on roof trusses.

15:44 – The innovation question. What it means at XFrame and what problems drive it.

18:14 – Expanding on roof trusses.

20:50 – International growth.

Pictures: supplied

Further reading

TONSLEY COMPANIES FOCUS ON INTERNATIONAL MARKETS

CEFC COMMITS $75 MILLION IN FINANCE FOR PINKENBA RECYCLING FACTORY

AUSTRALIA NEEDS CONSTRUCTION WASTE RECYCLING PLANTS — BUT LOCALS FIRST NEED TO BE WON OVER

NEW $18 MILLION CENTRE FOR TRANSFORMING CONSTRUCTION WASTE ANNOUNCED

Is your company one of Australia’s 50 most innovative manufacturers? We want to hear from you.

PUT YOURSELF FORWARD AT THIS LINK. NOMINATIONS CLOSE AT 5 PM (AEST) ON MAY 26.

WATCH OUR LAUNCH WEBINAR HERE.

![]()

Australia’s 50 Most Innovative Manufacturers is a new campaign by @AuManufacturing. It has been made possible by the generous support of MYOB, SMC Corporation Australia, and Bosch Australia Manufacturing Solutions. Be sure to check back at this website for regular updates including profiles of nominees and other information.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos