Silex tests full scale laser destined for uranium enrichment

By Peter Roberts

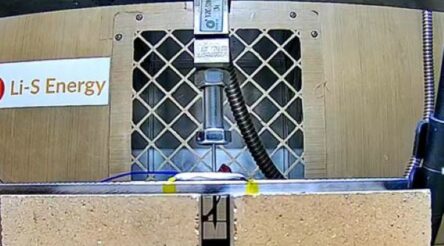

Australia’s Silex Systems has successfully manufactured and tested the first full-scale laser system destined for the enrichment of uranium in a major breakthrough in its decades long quest to commercialise what has been called third generation laser enrichment technology.

The company announced today the first full scale laser system module to be installed in a commercial demonstration plant in the US had successfully completed an extensive testing program at the company’s facility located at the Lucas Heights nuclear technology complex in Sydney.

The laser module has undergone eight months of testing under plant-like operating conditions and its production is a milestone in the development of commercial-scale equipment to be installed by Silex’s 51 per cent owned Global Laser Enrichment (GLE) company in the United States.

Silex has plans to build a facility in Kentucky to process and re-enrich over 200,000MtU of Department of Energy spent uranium tails to equivalent natural grade uranium hexafluoride (nUF6) product for sale in the commercial market.

Silex CEO Michael Goldsworthy told @AuManufacturing today: “This is a great example of Australian ingenuity.

“We have taken on some goliaths over the years, but now all the effort is paying off.”

Silex invented and developed the ‘SILEX’ laser isotope separation technology for enriching uranium in the 1990s and has been attempting to commercialise it ever since.

Goldsworthy said: “This is a pivotal milestone for the Silex uranium enrichment technology which demonstrates the ability of our laser systems to operate reliably at commercial-scale for extended periods.

“We congratulate our very talented and hard-working laser engineering team who have succeeded in the design, development and demonstration of this unique cutting-edge laser technology which will be utilised by GLE under the Silex uranium enrichment technology license agreement.”

Until now uranium enrichment has been performed by either gaseous diffusion and gas centrifugation, with Silex long recognised as one of the most advanced technologies available in the world for a third enrichment pathway using laser technology.

However, Silex has experienced numerous issues with commercialisation, including with various commercial partners including GE and Hitatchi, and concerns that the commercialisation of the laser pathway would make nuclear proliferation simpler and more widespread.

However Goldsworthy said if new players wanted to enrich uranium, they would use a simpler and better known process.

“The Silex system is extremely complex and challenging.

“It has taken us 20 years to get here, it has taken all that time to get a laser to commercial scale.

“There is just no proliferation issue.”

Goldsworthy said GLE, which is owned 51 percent by Silex and 49 percent by Canadian nuclear fuels group Cameco, had the capital to develop a demonstration plant and move to commercial production in the US. The company raised $40 million from investors and was ‘cashed up’.

Clearly the rubber is hitting the road for the deployment of the Silex laser enrichment system by GLE.

Earlier this year Silex put up its hand to develop nuclear fuel for small modular reactors (SMRs) – the development of new fuels for SMRs are supported by a US$700 million package announced by the US government and known as the high assay low enriched uranium (HALEU) availability program.

The newly tested Silex laser system module is now being de-commissioned and packed in preparation for transport to GLE’s ‘test loop facility’ and is expected to be installed by the end of this calendar year.

Goldsworthy said that the company was planning to complete the commercial pilot demonstration project by the mid-2020s after which a feasibility study would be conducted for a proposed enrichment facility at the shuttered US Department of Energy Paducah Laser Enrichment Facility in the US.

“GLE’s shareholders Silex and Cameco are currently assessing the potential acceleration of this timeline, with a view to commencing commercial operations as early as 2027, depending on market demand and other factors.”

Picture: Silex Systems

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos