Something in the water

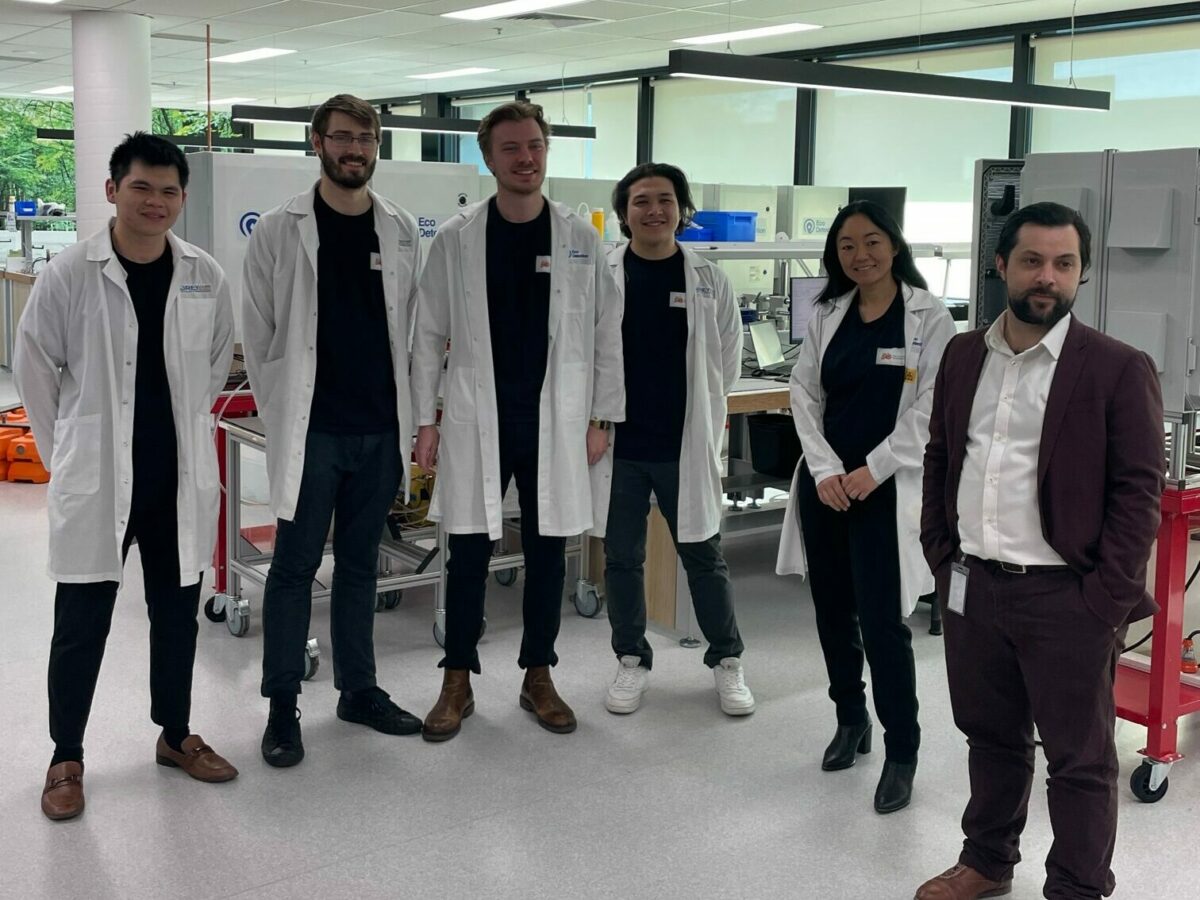

Eco Detection was a recent Top 10 Gold award winner in this title's Australia's 50 most innovative manufacturers campaign. Brent Balinski visited their Melbourne factory to learn about what drives their innovation program, and the role of local suppliers, customers and researchers in this.

The story of Eco Detection – which makes “lab in a box” solutions for wastewater, industrial and other clients – begins not with water but with a bang.

A program of research out of University of Tasmania following the Bali bombings was focussed on analysing fertiliser-based explosives, initially around post-blast analysis, explains Dr Phil Fox, CTO at Eco Detection since October 2021.

“The electrophoresis process was conducive to being able to separate out the individual components that might be used in a fertiliser-based bomb,” he tells @AuManufacturing during a visit to the company’s Richmond site, co-located with parent company Grey Innovation.

“So Grey Innovation come on board and they start developing and they turn that into the first system, which was for the explosives trace detection.”

GreyScan has raised somewhere between $25 million and $30 million, according to a recent interview with the founder of Grey Innovation, Jefferson Harcourt, and now sells explosives detection equipment around the world to customers in airport security.

Meanwhile, sister company Eco Detection has been applying electrophoresis to very different uses since 2018, where it is able to analyse water chemistry and quality and provide real-time updates on these to users.

Electrophoresis dates back to the 1930s, and is used for purposes including DNA and drug analysis. The Grey companies use capillary zone electrophoresis, combining electricity and microfluidics, to separate different substances into their component parts.

“We've… taken that process and developed it into a technique that's targeted much more for monitoring water quality, and particularly nutrients in water and inorganic ions,” adds Fox.

“We've… taken that process and developed it into a technique that's targeted much more for monitoring water quality, and particularly nutrients in water and inorganic ions,” adds Fox.

Eco Detection raised $8 million last year and has received recognition including a Victorian iAward for the best Sustainability and Environmental Solution this month and a Top 10 Gold award in July through this title Australia’s 50 most innovative manufacturers campaign.

According to the company, the second generation of water monitors, Ion-Q+, has particular usefulness in understanding ammonium levels in wastewater treatment plants. This allows operators to better calibrate aeration treatment, which is a major energy cost.

“You get a fuller picture of the chemistry in the water, but especially suited to the wastewater environment, where having that information on both the nitrate, the phosphate and the ammonium is really important for how you're managing the process in that wastewater treatment plant,” explains Fox.

The company’s R&D relationship with University of Tasmania continues, with a Linkage grant announced earlier this year including expansion into detection of heavy metals for mining environments and applications in marine settings.

According to the company, development has been greatly aided by the use of local suppliers.

This has been helped along by parent company Grey Innovation’s work leading a project to manufacture 2,000 emergency ventilators for the national stockpile, using over 99 per cent Australian-made components.

“Historically you've obviously had to go overseas to get small volume production cheaply, whereas now we've developed really strong engineering links between manufacturers and design houses, and that's critical,” Lachlan McLaren, Project Manager at Grey Innovation, tells us.

“And I know other companies similar to Grey Innovation have done that as well, and that's really fantastic.”

“And I know other companies similar to Grey Innovation have done that as well, and that's really fantastic.”

McLaren believes that hardware startups in Australia would benefit from better linkages with local suppliers, and in Eco Detection’s case this has made their products cheaper to build and more reliable.

“We've kept all our relationships from the ventilator project as key manufacturers for Eco Detection and other Grey Innovation group companies, and that's been fantastic for us,” he adds.

“They do testing on parts that you wouldn't get that level of testing and of line testing overseas. We have incredibly tight tolerances on things like the capillary and our fluidics pathways and… the analog electronics have to have very little noise…

“The suppliers that we work with provide us with all of that. So it derisks a lot of the manufacturing process for us. That's another opportunity to encourage that relationship between the design houses and suppliers to make substantial long-term linkages as opposed to quick one-off spends.”

In this episode of @AuManufacturing Conversations with Brent Balinski, Fox and McLaren tell us more about the company's story, the many uses of electrophoresis, the need for a better-linked ecosystem, and more.

Episode guide

0:20 – Introduction to guests

2:24 – An explanation of electrophoresis.

3:10 – How the company got started.

5:26 – Research and development, starting with understanding market requirements.

6:50 – The period from engaging University of Tasmania to commercialising GreyScan, and some of the things involved. “The capillary part was quite set, the electrophoresis, the CZE, that was quite set. It was all the infrastructure around that that took I think most of the development time.”

9:27 – Staff and what they do.

10:30 – Two iterations released so far.

12:20 – Where their customers are – environmental monitoring for rivers, compliance monitoring for discharge and wastewater.

14:27 – Ammonium monitoring and its use in wastewater treatment.

16:48 – The Linkage project with UTas.

18:20 – Nutrient runoff going into the Great Barrier Reef and the benefits of measuring this.

19:32 – Measuring inorganic carbon in seawater.

20:25 – How government procurement might drive new-to-market technologies.

21:18 – Why the National Reconstruction Fund needs to accept that some companies will fail, and to take risks.

22:50 – Lasting relationships from the notus ventilator project and why a better job is needed to connect manufacturers with design houses, contract manufacturers and others in Australia.

25:55 – Brokers have an important role in connecting manufacturers with suppliers.

Further reading

Grey Innovation delivers first ventilators to national stockpile

Celebrating Australian sovereign capability: some thoughts on the importance of procurement

$10.2 million in ARC Linkage grants announced for advanced manufacturing projects

Ventilator project lead wants to recreate ‘the model that changed the world’

Australia’s 50 most innovative manufacturers revealed

Australia’s 50 Most Innovative Manufacturers was a campaign by @AuManufacturing that concluded in July. It was made possible by the generous support of MYOB, SMC Corporation Australia, and Bosch Australia Manufacturing Solutions. You can download a summary of its findings here.

Topics Podcast

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos