Steel breakthrough – thyssenkrupp makes steel using hydrogen

By Peter Roberts

Steelmaking has always been the one area where even in the most carbon constrained industrial future imaginable, the world might just need to use Australian coking coal.

But now, thanks to an industrial breakthrough of truly massive proportions, the world may be left with very few critically important uses for coal.

German steel maker thyssenkrupp has demonstrated a blast furnace utilising hydrogen according to reports, eliminating coking coal from its century-plus dominance of steelmaking.

Thyssenkrupp Steel, Air Liquide Deutschland GmbH and BFI research institute combined to decarbonise the steel making process in tests which began in April at thyssenkrupp’s blast furnace number nine in the North Rhine-Westphalia region of Germany.

The partners began by injecting hydrogen rather than coal dust as a reducing agent into one of 28 injecting ports in the blast furnace.

The initial goal was to reduce CO2 production by 20 per cent.

It is success with these tests, foreshadowed in @AuManufacturing news, that has been reported this week.

Thyssenkrupp Steel Europe chairman Premal Desai reportedly said the tests were ground-breaking for the steel industry.

Desai said: “Steel production will play an important part in reaching our climate targets because the potential for reducing emissions is huge.

“That’s why we’re working flat out to drive the transition to hydrogen technology.”

However, the companies still have to progress their trials, and are planning to gradually increase the number of ports utilising hydrogen.

It is aiming to run at least three furnaces completely on hydrogen by 2023.

If steel can be made with hydrogen, and energy generated from solar and wind power (already more cheaply than from coal), only a few chemical and pharmaceuticals of truly critical importance are left to coal.

Coal is far from dead yet, but it may be time to start reading it the last rites.

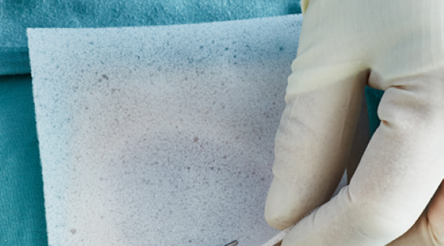

Pictures: Air Liquide

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos