USQ materials centre invests in fibre braider for advanced composite structures

The University of Southern Queensland has announced its Centre for Future Materials will receive a dual-ring 84/60 carrier braider from South Korea’s Textile for Life, enabling the production of advanced composite structures.

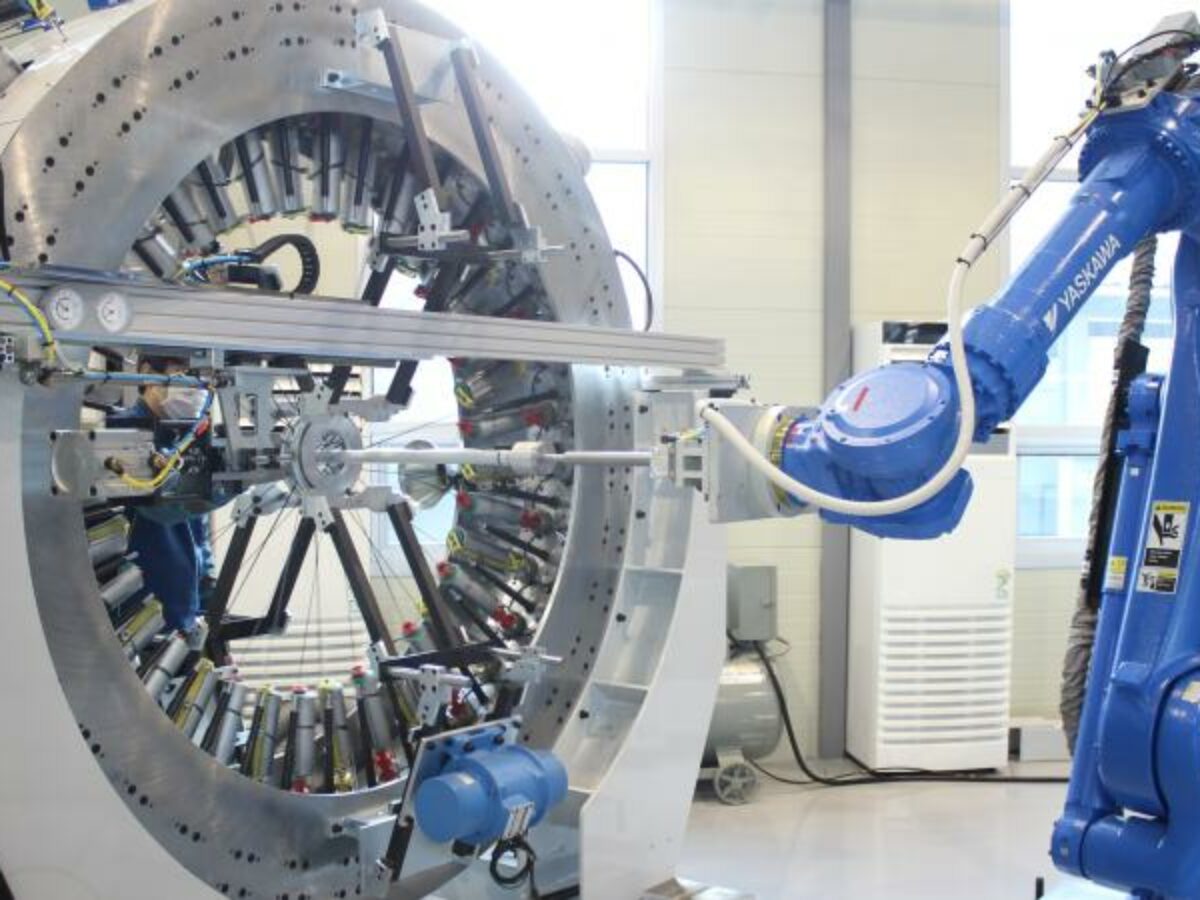

The machine would be able to braid “carbon, glass, Kevlar, thermoplastic and co-mingled yarns for the generation of complex lightweight dry-fibre preforms on industrial scales” said the university in a statement. The machine would be combined with a Yaskawa six-axis robot in a production cell, allowing for automated fibre placement.

“Pairing the new braider with USQ’s existing Pultrex pultrusion machine, an upgraded manufacturing line will be realised for highly tailored and optimised pultruded sections,” added USQ Research Engineer Dr Tristan Shelley.

The machine will be the first dual-ring industrial-scale braider in Australia, said USQ.

The news builds on a July MoU signing with the Korean machinery company T4L, said Shelley. It also follows news in September that CFM would invest $500,000 in analytic and other tools for composite manufacture.

According to the university, its Centre for Future Materials operates a test service for more than 1,000 business clients, and is involved in a CRC-P project with Wagners Composite Fibre Technologies on next-generation composite pultrusion sections.

Picture: Radial Braiding Machine for advanced composite preform (T4L)

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos