AML3D’s second US submarine contract in two days

Metal additive manufacturing company AML3D has announced its second new US submarine construction contract in the same number of days.

On Tuesday the company won a contract to develop and test 3D printing copper-nickel (Cu-Ni) components for the US Navy’s submarine programme.

The contracts, in tune with the AUKUS agreement, will run parallel with the recently extended Nickel-Aluminium-Bronze alloy characterisation, corrosion, and strength testing program AML3D is running with the US Department of Defence.

Today the Adelaide company revealed it had expanded US Navy submarine parts contracts with a further order for a one tonne prototype component in nickle-aluminium-bronze to support the submarine progarmme.

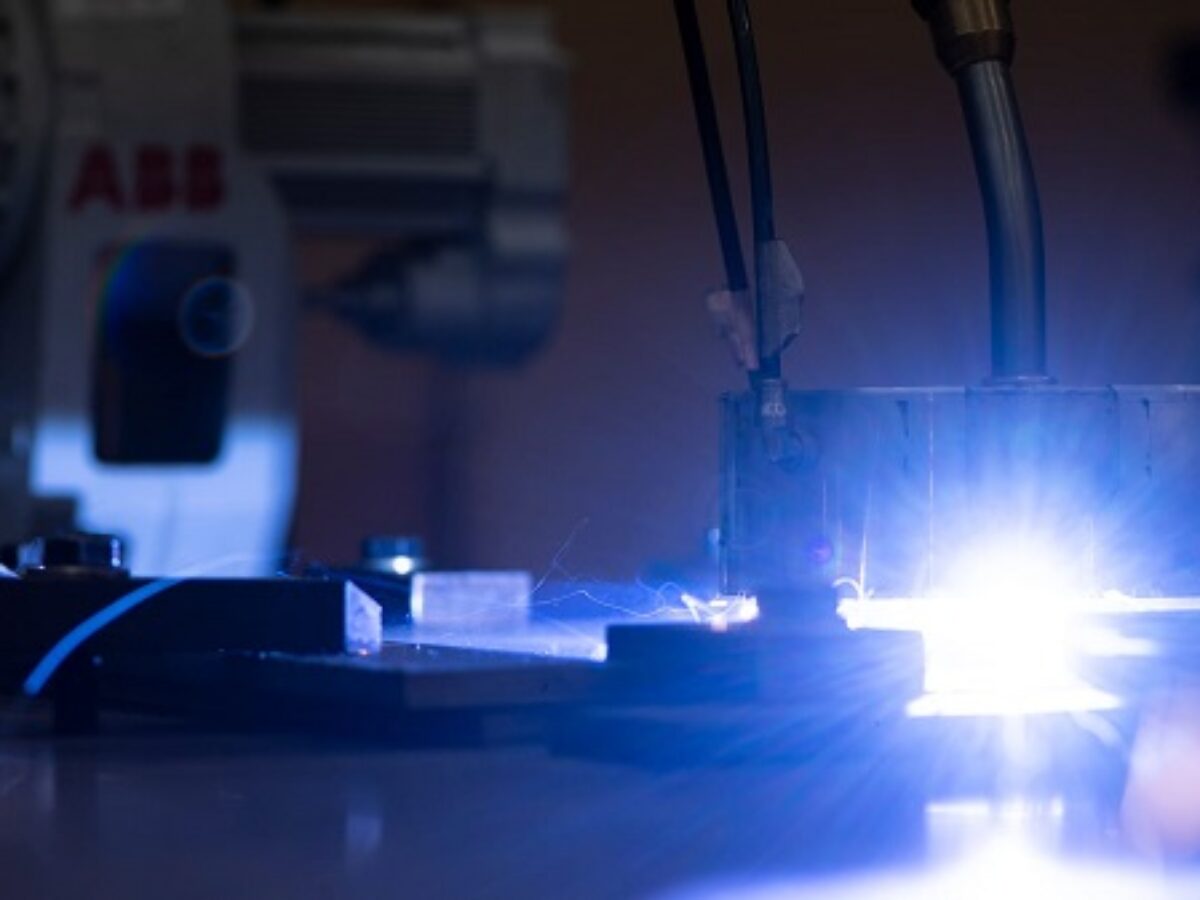

AML3D's wire arc additive manufacturing technology is particularly suited to very large scale parts.

Valued at around $600,000, the new order demonstrated the role the company can play in supporting the US submarine manufacturing industrial base, according to the company

“The manufacturing cycle for the new prototype component is expected to run for a period of 22-24 weeks and be carried out at AML3D's facility in Adelaide, South Australia.”

The company's interim CEO Sean Ebert said the order was another opportunity to demonstrate the company's cost effective, high efficiency, high quality additive manufacturing technology.

He said: “It is also a great opportunity to demonstrate the key role large scale ARCEMY systems can play within the US defence sector as point of need manufacturing solutions with the potential to solve supply chain challenges for the US Navy.”

Further reading:

AML3D wins contract to 3D print metal parts for US Navy submarines

Picture: AML3D

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos