Australia’s only watch manufacturer to split in two, target space industry

From its beginning as one of very few Australian assemblers of watches, Nicholas Hacko Watchmaker has developed the ability for in-house production of the vast bulk of its components as well. Brent Balinski spoke to the company’s Josh Hacko about its next steps as a contract manufacturer.

“Space to grow” is something we’ve been hearing for the last few years, with an obvious intensification after the space agency was announced in 2018 and countless subsequent achievements and deals since.

Last week applications for space project grants were invited, with the sector the first asked to put their hand up for a share in $1.3 billion budgeted for the federal Modern Manufacturing Initiative.

If space — or any of the six manufacturing “priority areas” — is to live up to its acknowledged growth potential, companies will arguably need to work together and coordinate and combine their efforts, in a local environment defined by its high proportion of tiny companies.

SMEs and micro-businesses will also need to rethink what they do, invest in themselves, and move into adjacent markets and new opportunities.

One manufacturer seizing new opportunities in space and elsewhere is Nicholas Hacko Watchmakers.

The company began designing, assembling and its own watches in 2013 after founder Nicholas Hacko, a third-generation watchmaker, saw himself and other independent repairers cut off from spare part supply by the big Swiss companies.

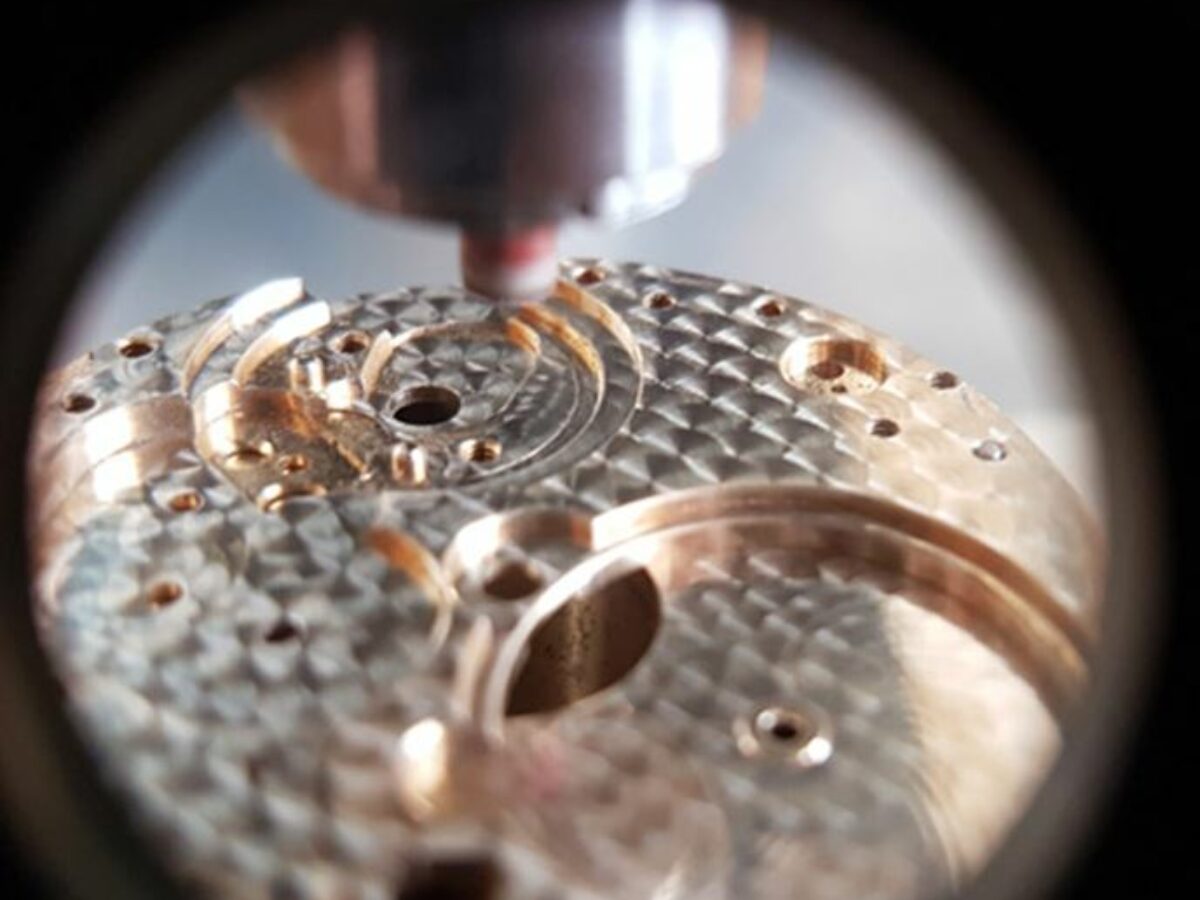

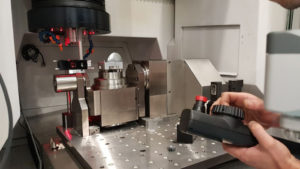

In 2016 it began making its own components, learning by doing (the European industry is reluctant to share its secrets) and building up its in-house expertise to the point where it felt comfortable calling itself a manufacturer — and Australia’s only one — of watches. It began with turning, then CNC milling, gear hobbing and wire EDM.

It is now at the point where it can make 85 per cent of its watches’ content in-house. It has capacity to make around 100 a year at current levels of staffing and equipment.

Last year it stretched out a little further by offering watches made out of the specialised titanium alloy Timascus.

Picture: http://nickhacko.blogspot.com/2019/09/timascus-for-nh2.html

The year also saw demand for its contract manufacturing services, which previously made up about 5 per cent of revenues, creep up to 20 per cent. It plans to keep growing this, and to keep growing staff numbers, including two additional apprentices a year.

Josh Hacko, Nicholas’s son and the company’s technical director, says 2021 will see the company split the two sides of the business into separate companies. He explains the opportunity in Australian space and other specialised manufacturing below.

@AuManufacturing: Why are you doing more outside of luxury watch production, which was your focus when we visited in late-2018?

Josh Hacko: We didn’t advertise, didn’t market our capabilities. It was just sort of word of mouth or people who had the intuition to realise that watchmakers make small parts and then sent us RFQs. But that was minimal… From about August 2020 onwards, it’s been probably close to 20 per cent of our revenue.

The general rule of thumb is we serve anyone that needs ultra or high precision parts. And that manifests itself in Australia in the medical industry, doing not necessarily medical-facing parts, but jigs, fixtures, tooling, any sort of support work. And usually toolmakers do that sort of work, but the toolmaking industry in Australia has dwindled off to almost non-existence.

@AuManufacturing: What is some of the space-related work that’s come into your machine shop?

Josh Hacko: We clicked with a research group looking for a manufacturer for these really quite insane parts in terms of tolerances. They had been searching for a supplier for a while, and no one in Australia could really do them.

@AuManufacturing: What are you making?

Josh Hacko: The start of the relationship was, again, jigs and fixtures for the assembly of some of these optical components. They used the jig we made for assembling glass elements in a telescope. And then later we started making aluminium structures that the glass elements fit and bind to. Those aluminium structures move around and enable the users of the sensor to inspect different parts of the sky. I’m doing that no justice, because it’s designed by people with multiple PhDs, but that’s where the project sort of transferred to.

We’ve also had the opportunity to quote and to manufacture a bunch of parts internationally from a few manufacturers in the south of Germany. They needed some precision parts, and we were not competing on capability like we were in Australia, but rather we were competing on price. So we could do the parts at a more affordable price than they could find locally in Germany. Similarly, we’ve manufactured parts for the watchmaking industry, but for other watch manufacturers overseas in the US and in Germany and in Switzerland.

@AuManufacturing: It’s not often you hear about an Australian company exporting and competing on price, to Germany or anywhere else, so good for you.

Last time we spoke, you were talking about making a movement in-house with about 60 percent manufactured content. What has progress been since then?

Josh Hacko: The NH1 was our first release. That was a movement that, as you said, had about 60 percent of its parts made by us. And since then we developed NH2. We transitioned into a completely different metal to what we were using before. We’re using a brass that was gold plated afterwards, and with NH2 we started using a material called Timascus. Long story short, we were the first people in the world to use Timascus for the internal components in a watch. Growing on that, we developed NH2.1, where we increased the number of parts we made to about 85 per cent. We could make more, it’s not really a technical challenge anymore, but it’s rather an expertise challenge. We need to do a lot of R&D to push it up further, but it also, without getting too specific, that last 15 per cent could cost more than the first 85 per cent.

@AuManufacturing: What do apprentices do to learn watch manufacture? There is very little here to speak of in terms of a watchmaking culture or an industry.

@AuManufacturing: What do apprentices do to learn watch manufacture? There is very little here to speak of in terms of a watchmaking culture or an industry.

Josh Hacko: We have a very specific pathway for apprentices. A lot of it is a self-developed program because the skills we’re looking to harvest are all very specific. There’s currently a program at Ultimo TAFE for watch and clock repair. That course is useful, but doesn’t give us any significant advantage for the manufacturing side of the business. It’s for repair of watches and clocks.

So we try at least to train all our apprentices in a program where we expose them to manufacturing, where we talk about the precision parts of the manufacturing process. We talk about the hand finishing parts of the manufacturing process — that’s polishing and decoration — as well as the watchmaking side of the whole business. We try to split that around 30 per cent manufacturing, 70 per cent watchmaking.

And usually the apprentices find their groove and figure out they really like manufacturing or hand decoration or the watchmaking side. They sort of end up specialising after a few years.

We are regularly looking to hire new people and bring young people into the industry. We have apprenticeship positions open as well as engineers and everything in between. Hiring two apprentices or two employees per year for the next five years is sort of the goal.

@AuManufacturing: What sorts of tolerances are you working to for your components, in terms of milling, turning, gear manufacture etc?

Josh Hacko: About 90 per cent of our components contain tolerances that are tighter than plus or minus 10 micron. And I’d say of those 90 per cent of parts, 50 per cent of those parts contain tolerances that are even tighter. So we talk about the position of bores, the size of bores, the flatness of these parts to within plus or minus two micron, and we regularly manufacture these parts in quantities and batch sizes larger than 50. We make 100 parts and they’re all within 2 micron of the design value.

What we found really early on was that we had to invest nearly as much money into our metrology and QC equipment as we did to our manufacturing to verify these results.

That was a journey that I guess a lot of people don’t realise that you have to take to make precision parts. They sort of think, ‘I’ll just buy the most expensive machine that I can afford and then pray.’ But unless you have the metrology equipment to verify your micron hole size, it’s pretty much useless, especially when you look to manufacturing for other people.

@AuManufacturing: You also mentioned last time we spoke that you’re looking to move to Mittagong. Is that sort of on ice?

Josh Hacko: It was until about a month ago, we sort of outlined our plans for the next two to three years. Our goal currently is by 2023 to be in Mittagong. Originally when we bought the plot of land at the end of 2017, we aimed to get in by 2021. But we realised that to do the project right from a technical standpoint we’d have to invest more money than we anticipated. That means building foundations that are thick enough to support the machines, separate air conditioning systems to maintain temperature in all the rooms, vibration isolation pads, things like that that you have in the back of your mind, but until you get a quote on execution don’t really understand how much it’s going to cost.

Currently we’re designing the place from scratch, engaging with architects and hydraulic engineers and structural engineers and all that to make plans for the place and apply for a DA. Beyond that sort of little bit murky. But the idea is to build.

@AuManufacturing: You touched on a space-type project earlier. What can you say of further work you hope to accomplish in this area, which the federal government has deemed one of the big six of Australian manufacturing?

Josh Hacko: We are interested in making high-precision or ultra-precision parts, but also to support growing Australian businesses.

Picture: nickhacko.blogspot.com

We ourselves are a small, growing and very capable Australian company. We recognise that there’s tens and maybe even hundreds of businesses like us that possibly need our services. Our doors are open, and that’s a very rare thing to hear when it comes to the space or medical industry or all these slightly secretive industries where people don’t want to disclose too much information or help others and all the rest. But we’re completely isolated from the space industry or the medical industry or the toolmaking industry, so we can freely offer our services. Well not truly free, but at a cost, to other businesses.

An example of that is a small startup run by some young Australians, and just last week they asked if we could do a very challenging application of drilling some ultra-small holes, 60 micron holes, in challenging materials. And we said yes, even if we did the R&D for a project like that on our own dime. We’re interested in national interest projects.

Besides growing our manufacturing services, the business’s main goal for 2021 is to split into two definable entities: the contract manufacturing side and the watchmaking side.

Very few people can claim that they started there. And the significance of that is great, because watchmakers work with tolerances that are usually tighter than what most people demand. When we hit plus or minus 10 micron, it’s not a relief, it’s normal. Although many applications don’t require plus or minus 1 micron or half a micron, if we can achieve one micron on a part easily, 10 micron becomes — not easy, but it becomes easier.

Featured image: nickhacko.blogspot.com

Subscribe to our free @AuManufacturing newsletter here.

Topics Analysis and Commentary

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos