Holiday manufacturing news briefs – stories you might have missed

Next generation Hadrian X robot completed

Perth robotic technology company FBR has completed mechanical assembly of the first next-generation Hadrian X bricklaying robotic system. The next-generation Hadrian X is designed to be able to lay at speeds of up to 500 blocks per hour, equating to up to ~120m2 of wall per hour. This has the potential to complete both the external and internal walls of a standard double brick house in a single day. The new Hadrian X features a shuttle block delivery system designed to lay any existing commercially available block, as well as the ability to lay blocks not yet available and measuring up to 600mm x 400mm x 300mm and weighing up to 45kg. The shuttle delivery system is also designed to be adaptable to handle other products such as roof tiles. The system also features a lengthened 32 metre telescopic boom arm.

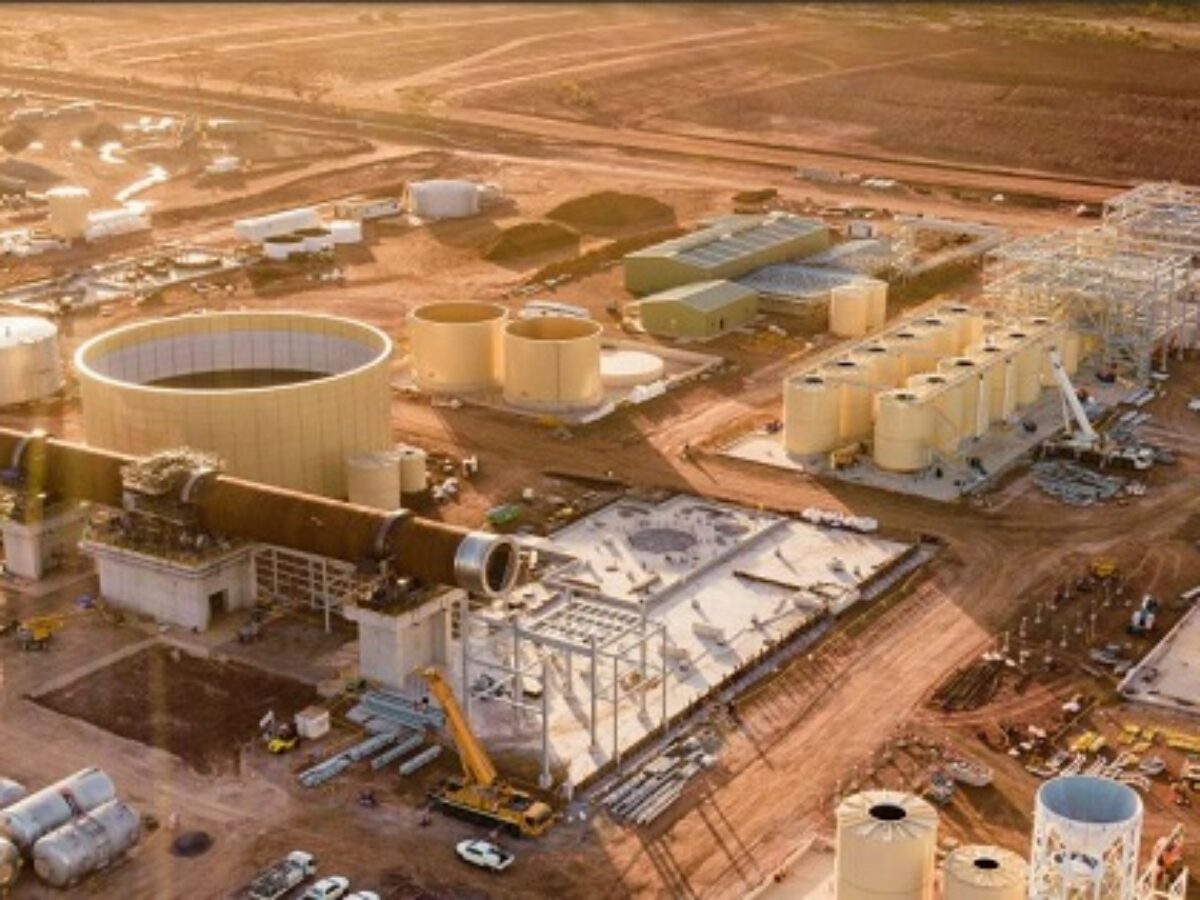

Lynas Rare Earths to start up Kalgoorlie processing plant

Critical minerals producer Lynas Rare Earths will begin production at its Kalgoorlie, Western Australian cracking and leaching processing facility (pictured) in July this year. The processing plant is designed to feed its Malaysian metals plant which has been hit by environmental restrictions which require the company to cease processing radioactive ores. However the company has now asked the Malaysian government to lift restrictions on Malaysian ore processing, even after the Kalgoorlie plant comes online. According to Channel 9 media reports, this is to allow for a doubling of production of the metals which are critical to high technology products. Lynas chief executive Amanda Lacaze told the company's November AGM that a $500 million expansion of its Mt Weld mine was advanced, with the processing plant to be completed in July. Lynas is also progressing plans for its new US heavy rare earths processing plant.

K-TIG sells fast welding system to Irish brewery

Fast keyhole welding system manufacturer K-TIG has received a $600,000 purchase order from Ireland based Brewery Chemical & Dairy Engineering for a Linear Precision Grow Line Circumferential Welding System. The system will be installed in BCD Engineering’s Stainless Steel Process Vessel & Process Plant following its manufacture in the UK and Australia. This sale represents the largest turnkey welding cell order received since the announcement in November 2021 of K-TIG’s intention to diversify its products by adding integrated Industry 4.0 compatible automated welding cells. K-TIG Managing Director Adrian Smith said: “This sale builds upon previous pipe welding cell sales that K-TIG has made in recent quarters and validates the decision to supply turnkey welding cells to our market. Our customers are generally looking for fully integrated solutions rather than torch technologies that require them to integrate with automation, and by supplying turnkey solutions we can significantly grow revenue and margin”.

Spiral Blue edge computer launches to space

Spiral Blue's Space Edge Computer (SZE-1) has been launched into space from Cape Canaveral on board a SpaceX rocket as part of a rideshare mission. The company's edge computer will interface with a Satellogic NewSat spacecraft's high resolution imaging system, processing images for applications such as cloud detection, ship detection and data cropping and compression. The mission will complete Spiral Blue's flight testing programme for its technology which streamlines data transmission the Earth by completing some computing tasks in space. The goal is to integrate these capabilities with Spiral Blue's Space Edge services platform, enabling customers to task a satellite to capture images and carry out onboard processing. SE-1 is the fourth Spiral Blue computer to reach orbit.

SunDrive's new research project with University of Sydney

Cutting edge solar cell manufacturer SunDrive will begin a research project to commercialise its perovskite-silicon solar PV cells. The company, which claims the world's most efficient solar cells, will work with the John Hooke Chair of Nanoscience at the university’s School of Physics and Sydney Nano Hub in the project. The work is backed by a $2.78 million research grant from the Australian Renewable Energy Agency. The work will focus on placing perovskite on top of silicon to form a ‘tandem solar cell', rather than using silicon on its own.

Bradken expands in South American manufacturing

Engineering firm Bradken has purchased its first manufacturing asset in Souith America, buying producer of wear protection materials for grinding mills, Linings S.A. Bradken, now part of Hitachi Construction Machinery, is expected to benefit from Linings’ specialisation in the manufacturing of composite mill liners, rubber mill liners and products, anti-wear plates, wear-resistant ceramic plates and metallic structures. Linings’ mill liners reduce cylinder weight by 40 to 60 percent compared with comparable steel mill liners, reduce energy demands, dampen noise and decrease grinding ball consumption. The acquisition of Linings aligns with Bradken’s strategy to meet the consumable needs of mineral producers and expand its manufacturing capabilities.

Skykraft satellites reach low Earth orbit

Skykraft's Block II satellites successfully reached low Earth orbit after their 3 January launch by SpaceX from Cape Canaveral. The satellites were launched as a single payload, with four mission satellites carried by an orbital transfer vehicle. Skykraft has performed critical operations including testing communication through its UHF command channel to communicate regularly with all satellites, ensuring a functioning power system with batteries being recharged by the solar panels, and operations of the mission computer. Skykraft CEO Dr Michael Frater said: “All onboard systems tested on the five satellites are performing in line with expectations, including the mission computer which is operating flawlessly. Skykraft is now actively operating the five satellites, which form the largest ever constellation of Australian built spacecraft, and will be carrying out proof of concept activities for our Air Traffic Management services” Skykraft's global Air Traffic Management (ATM) service is set to be commercialised over the next two years.

Picture: Lynas Rare Earths/Kalgoorlie processing facility under construction

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos