New recycling method sees stronger fibres recovered from composites

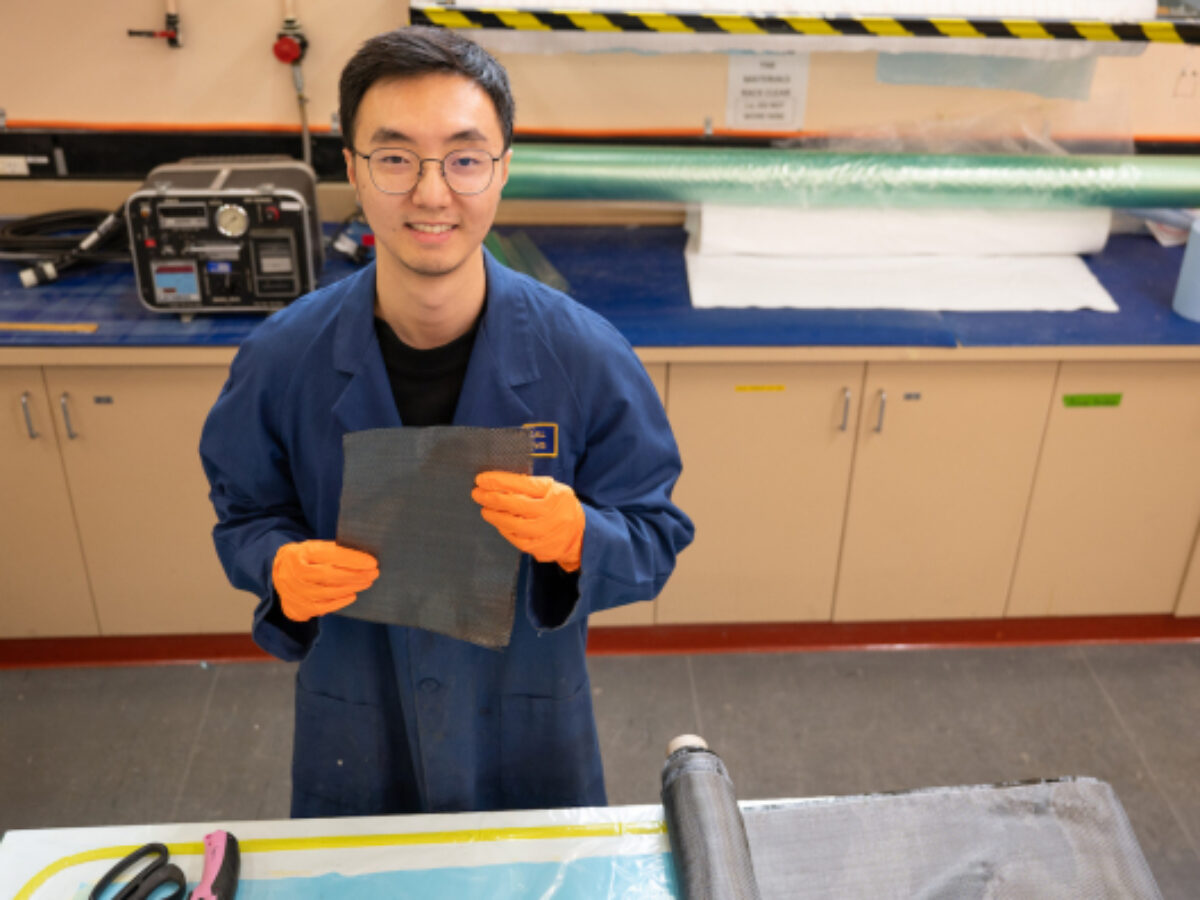

A UNSW Canberra engineering researcher has developed a method to recycle carbon fibre which saves energy and can recover more of the material, according to the university.

Carbon fibre composites are found in many applications with environmentally-friendly aims, for example in wind turbines and lightweight structures for transport. However, fibres have proved difficult to recycle, with their properties diminished if they can be recovered from end-of-life structures.

Lead author Dr Di He (pictured) investigated recycling composites in collaboration with Ford Motor Company, the ARC Training Centre for Automated Manufacture of Advanced Composites, and others, with a new paper published in the journal Composites Part A: Applied Science and Manufacturing.

Previously, recycling attempts had seen the mechanical performance of new items created out of old fibres “degraded by 80 to 90 per cent” versus new fibres, said He in a statement on Monday. This has limited their use to lower-performance, lower-value products.

“The existing method of recycling involves shredding the composite, which destroys the carbon fibre, before heating it to remove the plastic. After it has been shredded, the fibres look like individual hairs or cotton wool strands,” he added.

“In our method, we don’t shred the carbon fibre and we optimised how we heat it in a furnace.

“This leaves the fibres intact, and therefore the new product made from the recycled carbon fibre is much stronger.

“Our method degrades the carbon fibre by less than 30 per cent, which is a 50 per cent improvement on existing methods.”

The resulting fibre isn’t suitable yet for building a car, but is “significantly closer to that goal than before” according to UNSW, and could potentially be used to make certain components, “such as a roof.”

The paper can be accessed here.

Picture: credit UNSW

Further reading

Carbon fibre and composites recycling breakthrough

Carbon fibre composites – reuse, repair or recycle?

Surfboard startup shaping a solution to composite waste problem

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos