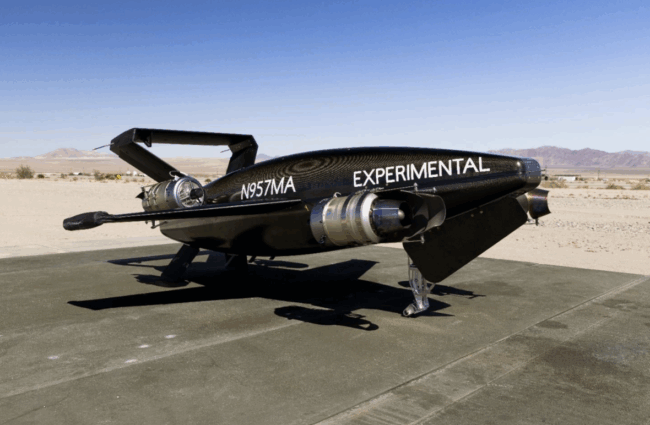

Aurora Labs partners with US aerospace company for 3D-printed aircraft engines

Australian 3D printing specialist Aurora Labs has signed a memorandum of understanding with US-based Mayman Aerospace to explore collaborative development of 3D-printed micro gas turbines for advanced aircraft propulsion systems. The two-year partnership marks Aurora Labs’ first entry into the US aerospace and defence technology ecosystem, representing a strategic move to penetrate the lucrative North…