Things heating up for composites specialist

By Brent Balinski

One of the success stories of the Cooperative Research Centres program, which has been running since 1990, was the CRC for Advanced Composite Structures.

Founded as the CRC for Aerospace Structures in 1991, it was restructured as the CRC for Advanced Composite Structures in 1997 to reflect a broader set of industry partners and projects. Before it finally wound up after a fourth term in 2015, it was the longest continually-running CRC.

Its impact spanned numerous sectors, with one standout being its involvement developing processes leading to multi-billion-dollar exports for Boeing Aerostructures Australia.

A spinout company from the CRC, Advanced Composite Structures Australia, continues its work at the forefront of composites engineering. ACS-A marked 30 years of this in late-2022. In July, it was part of this title’s Australia’s 50 most innovative manufacturers list.

Projects at the company of about 25 are awesomely varied, from animatronic dinosaurs to metal organic framework-based hydrogen storage to hypersonic vehicles, all underpinned by Australian IP developed over decades.

“We’re a company now which basically does similar to what that CRC did, except as well as doing the engineering services-type work that we do — with a sole focus on using composite materials and structures – we’ve also expanded that to… series manufacture for our customers,” General Manager Dr Paul Falzon tells us.

“We’re not what you’d call a build-to-print company, but we do manufacture products that we develop.”

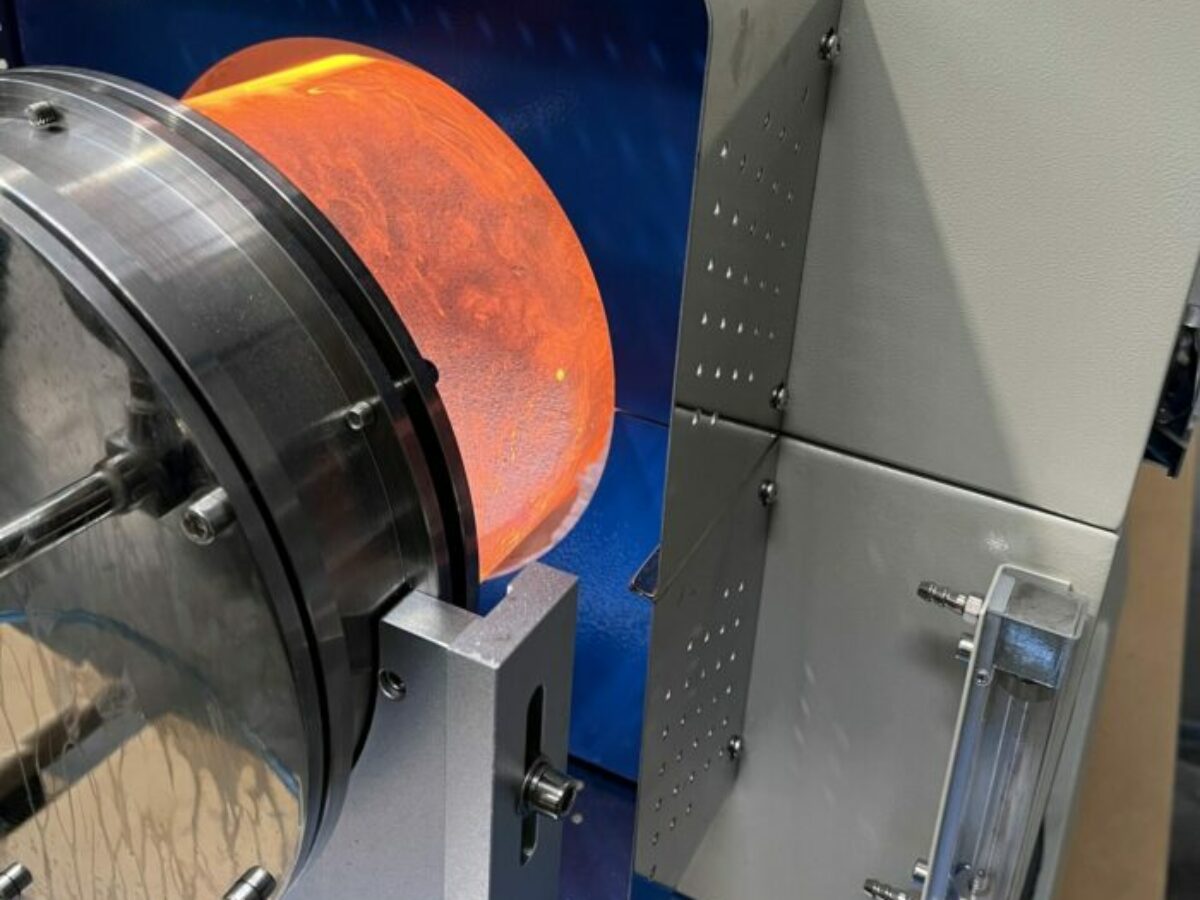

For the last three years it has pursued structures for ultra-high-temperature application, in collaboration with the Defence Science Technology Group.

“So in hypersonics, or it might be in re-entry vehicles, in componentry for rockets and so on,” adds Falzon.

“And that process really involves traditionally producing what we call a green body. So it’s really a composite structure that’s manufactured using a more of a conventional process. And then it gets converted to a carbon-carbon or ceramic carbon material. And that requires a pyrolysis-type process.”

In this episode of @AuManufacturing Conversations with Brent Balinski, we hear from Falzon, in a lost-then-found recording made during our Australia’s 50 most innovative manufacturers campaign earlier in the year. He tells us about projects at the pinnacle of composites engineering and manufacturing in Australia.

Episode guide

0:26 – A brief company history

2:38 – A brief personal history

4:40 – The skillsets present at the company, including aerospace engineering, material science, boat builders, simulation and structural analysis.

5:55 – Emphasising the “advanced” in advanced composites.

6:54 – High-temperature work and what it requires in terms of materials.

7:43 – Recent work in structures for wave energy generation with Carnegie Clean Energy

7:43 – Recent work in structures for wave energy generation with Carnegie Clean Energy

9:00 – Projects in ultra-high temperature composites over the last three years. Green body and pyrolysis processes.

10:13 – A first step into hydrogen storage. Where a new filament winder could be used.

11:20 – What innovation means at the company.

12:24 – The new Lorimer Composites program and its role in company culture and staff satisfaction.

15:20 – Supply chain issues in composites and the reliance on overseas suppliers for ultra-high temperature inputs.

16:45 – How the skills shortage is affecting ACS-A.

Further reading

Excellence in maritime manufacturing – material gains for maritime

MoorPower wave power project gets underway

Fibres and composites transforming industry: Composite repair and sustainment

Australia’s 50 most innovative manufacturers revealed

ACS delivers composite hydro-electric turbine blade

Composite creatures developed for theme parks

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos