Wanted: Australian manufacturers to support small satellite sector

Brent Balinski speaks to William Crowe, co-founder of University of NSW-based High Earth Orbit Robotics, about what they have achieved so far and what businesses in the burgeoning nanosatellite industry expect from potential suppliers.

For Aussies interested in space, this month is an especially exciting one. July 20 is the 50th anniversary of the moon landing. Australia’s role in broadcasting this stellar achievement to the world will rightly be celebrated at various events.

It is an exciting time for Australian space buffs for other reasons as well.

Venture capital and government investment aimed at growing a local space industry have stepped up in recent years. The country finally got a space agency. There is a target to triple the size of the Australian space sector by 2020, to $12 billion and 30,000 jobs. The last federal budget also saw an additional $19.5 million earmarked for infrastructure to aid in this.

But is enough being done? Comments in the last month from by Badri Younes of NASA and Adam Gilmour of Gilmour Space Technologies suggest it’s not. And how well is the local supplier base positioned for the predicted jump in small satellites to be assembled, launched, and tasked with various types of data collection?

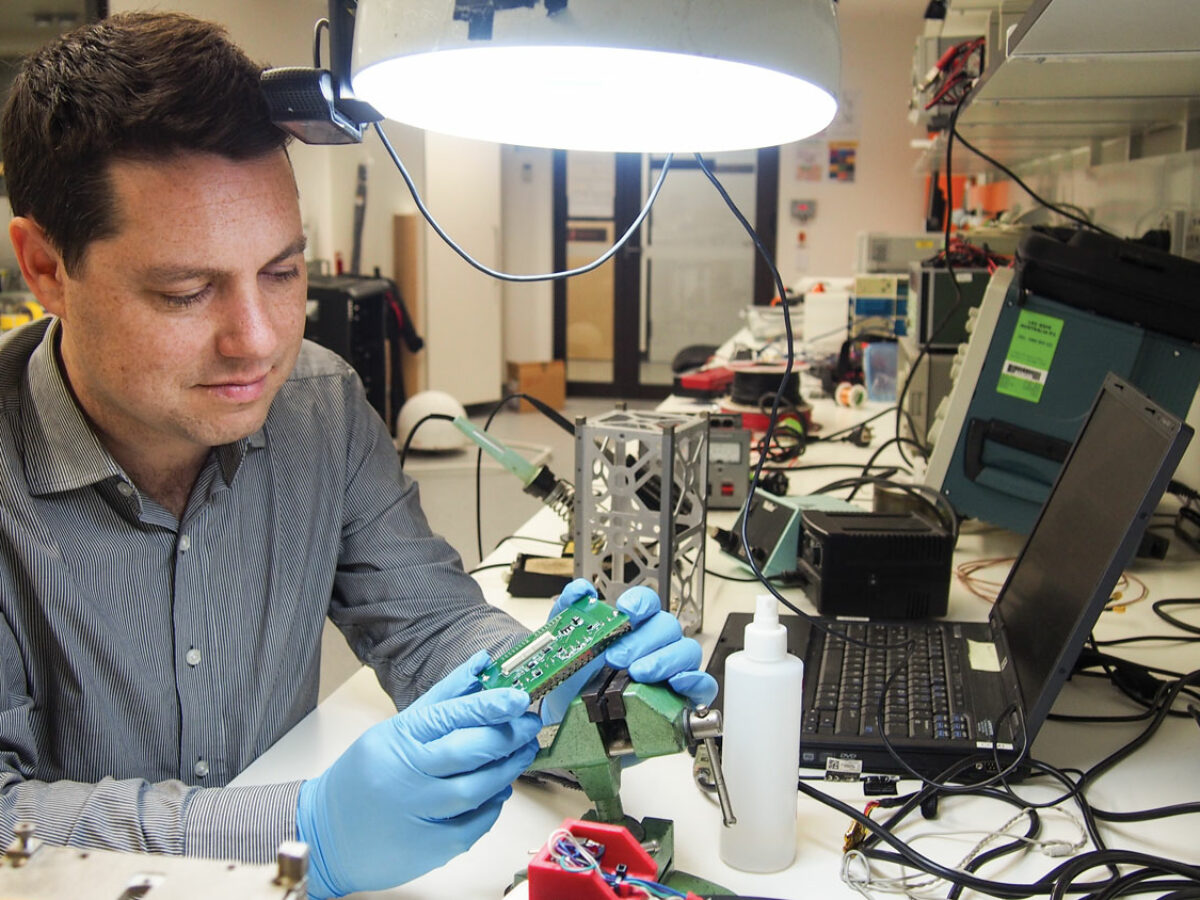

High Earth Orbit Robotics is one Australian startup on its way to building and launching nanosatellites. It was founded in 2016 by William Crowe, a PhD in Astrodynamics, and Dr Hiranya Jayakody, a mechatronics specialist.

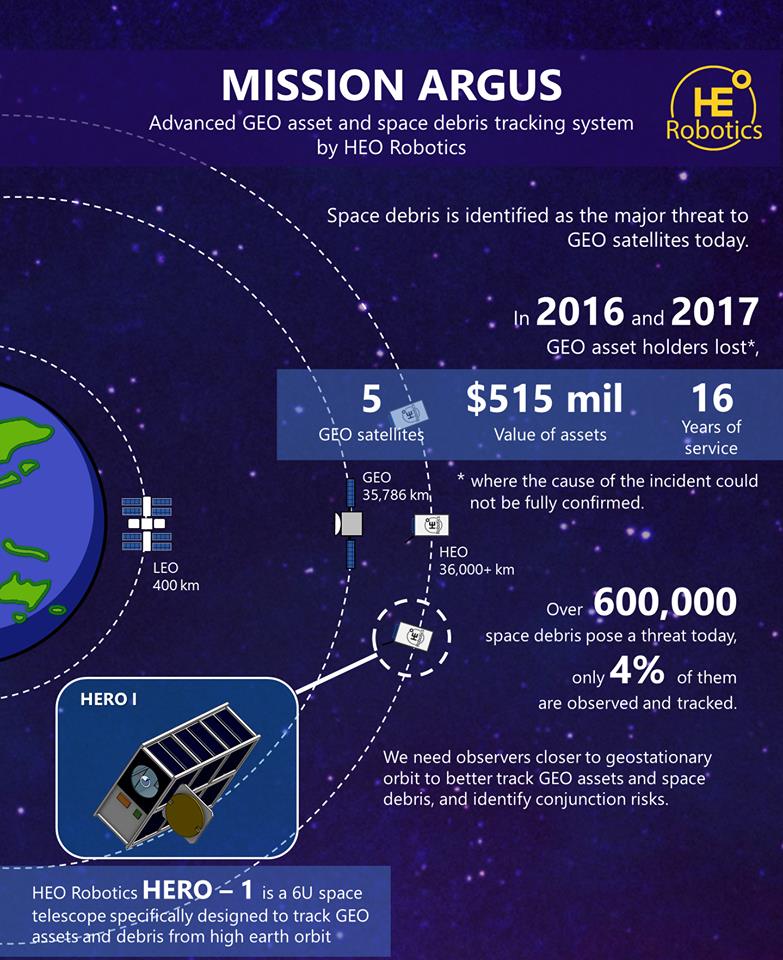

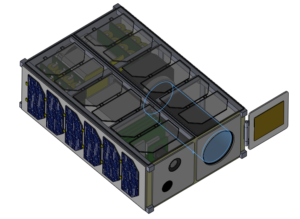

HEO aims to operate constellations of cubesats with high-resolution RGB telescope payloads and powered by ion thrusters, located in high earth orbit (36,000 km above earth, hence the company’s name) and monitoring satellites in orbit below.

It plans to eventually have its imaging cubesats eventually prospecting asteroids for mining, but on the way it will develop and offer solutions for satellite operators. Among these planned applications are health checks on satellites and debris monitoring. Building, launching and operating a satellite is not cheap, and it wants to sell safety to those who’ve made the investment, providing them with intelligence on potential hazards.

This March, HEO was invited to the Defence-sponsored capability and equipment demonstrator, SpaceFest 2019, held at Woomera. This is another milestone for the company, which is seeking providers for its subsystems and other components.

HEO is currently looking to Australian businesses to source its subsystems, and is planning in-orbit testing this year. Crowe discusses the opportunities for local manufacturers wanting to supply space businesses, what HEO is looking for from them, and goals for the near-term.

@AuManufacturing: We haven’t spoken since late-October last year. What has been going on?

William Crowe: What’s probably most interesting is that we’re starting to get to the point where we demonstrating our work. A few months back we did a paid technology demonstration at Woomera with the space situational awareness team with the Royal Australian Air Force. And we were able to really prove out our technology and high-fidelity simulated environment, which was fantastic.

And then the next step from there is to get spaceborne.

Annoyingly, I can’t tell you everything today, but we’ve got some exciting projects in the pipeline. Some of them are using existing assets in space, and some are using assets that we’re developing.

@AuManufacturing: Tell me about the Woomera simulation. What exactly were you showing off there?

William Crowe: So we were tasked with investigating a few targets, along with a number of other companies, and what we did in particular is that we simulated our swarm, which is a self-directed constellation of satellites.

And we would direct them to observe the target, and then they would deploy in the simulation to get to that target. This simulation was as real-world as it could’ve been, because we set the simulation going before the event started, and then we just kept it running as the event went on. So for all of the targets that we saw, our spacecraft weren’t necessarily in the best position to go see them, but we were still able to get a good observe in the simulation of all these targets. And really what we were trying to do there is see if we can give the defence and the commercial sector a real ability to quickly understand what anomalies might’ve occurred on highly valuable satellites, in geosynchronous orbit in particular, and do that within 12 hours of being tasked to do so, which is just not possible today.

@AuManufacturing: I saw some statistics on your website saying around 10 nanosats had been launched, built, operated in Australia in the last three years, and in the next three years that number is expected to be something like 100. Can I just get your point of view on how quickly things are ramping up?

William Crowe: I think things are ramping up really quickly. I think that number is probably true or it’s a very similar number. I’m still bullish on a higher number coming online over the next several years. A lot of companies who have the funds together are procuring satellites now. The majority of them aren’t built within Australia, the majority of them are built overseas still, which is all a bit of a shame.

They’re all Australian-owned and built for Australian purposes as well, so I think the remote nature of the country is a particular one that people are trying to solve with satellite technology. So planning a nanosatellite is on the horizon still.

@AuManufacturing: Tell me about the local ecosystem of suppliers. What does that look like? You were mentioning that you’re looking to, if it’s possible, use Australian content for your satellites. What’s out there now and what needs to happen?

William Crowe: There are two – nanosatellite in particular – building companies today. Inovor Technologies and Skycraft are two companies looking to build spacecraft in Australia. One thing that we’ve found is that it’s still easier to talk to nanosatellite builders overseas, and maybe some of the pressure’s on us as well as the other suppliers in Australia. But really what we’re missing is a bit more of an industrial base to get things started. Probably something that’s important to note is that overseas the nanosatellite suppliers really floundered where there were a couple of big science events where 50 or more nanosatellites were being procured around the same time.

For example, there’s a company called GOMspace in Denmark, who we work with, who were renowned to have equipment that often failed about five years ago. What’s happened in the last two years is that they’ve now become renowned to not only have high-quality parts that don’t often fail, but also they’ve created a factory and they’re really bringing down the procurement timeline as well, which is really important. The reason they were able to do that was because a lot of the people building cubesats for these large science missions were based out of Europe, or based in countries that were European-friendly. So they were able to buy a whole bunch of parts, and these guys were able to scale up their operations and take out a lot of the defects from their products as well. I think that’s something that’s needed in this country as well.

@AuManufacturing: What are you looking for in terms of components? What are you looking to qualify and to source?

William Crowe: We’re looking to source all the sub-systems for the satellite. Something that Australian industry could be good at are things like building the chassis, which is a reasonably low-cost part to build and generally requires aluminium forming and machining, which we’re quite good at.

The trick there is to build a chassis that people trust for space applications. And there’s a few testing processes to go through; probably the big one is vibration testing. And getting the measurements right. Having a satellite that’s going to fit within deployers is extremely important. Being a millimetre off is not an option.

Really, what we’d like to do is put the call out to non-traditional suppliers. So we have Skycraft and Inovor, which is great, but it would be also great to really start to understand who out there might want to take on this challenge and start to supply the space ecosystem. I think it could be a really good news story for government and for the new space agency if we have a whole bunch more suppliers in Australia that could supply Australian-built space hardware that we could then sell both domestically and internationally as well.

@AuManufacturing: It certainly seems like there’s going to be the demand for it.

William Crowe: Not super-high demand, but it’s generally higher value per unit sold.

@AuManufacturing: I don’t mean demand as in a huge number of units, but relative to what things were a few years ago.

William Crowe: Absolutely, yes.

@AuManufacturing: Tell me about your end users. What sort of demands will they have around reliability from you and your supply chain?

William Crowe: They need absolute reliability! [Laughs.] One thing that’s interesting about our satellite is that we’re operating in proximity to other satellites, and we don’t want to cause any damage to them, so we need to be highly reliable, Having everything tested on Earth first and preferably having in-orbit tests are very important to us, but we’re willing to work with suppliers to help them understand what we need.

@AuManufacturing: And are standards pretty well-defined and easy to get your head around?

William Crowe: Absolutely. I think one of the confusing things about satellites is that the main standards are about how you put everything together. The majority of standards are their internal company standards. So we’ll have our own standard, which is a little bit annoying, but at the end of the day you don’t want spacecraft either being destroyed on the rocket when it’s going up in the high-vibration environment, and you also don’t want parts to fail due to radiation exposure in space. So having things radiation-tested on Earth is very important. And also around having debris creation events. If something hits you, you want to be as certain as possible that you don’t create more debris from that impact.

@AuManufacturing: You are planning to have 12 satellites in your constellation eventually when it’s up and running. I imagine you’ll have to build more than that, because things go wrong. Tell me about scaling up manufacturing and how you plan to do that.

William Crowe: That’s a huge issue for us. I think we’ve still got the first few units planned out, but going to that next level is going to be a real challenge. We’re trying to work with our partners at the moment to figure out how that might be done, and there’s a bit of infrastructure being built. In New South Wales, in particular, there’s a real interest in having satellite manufacturing based at the new Aerotropolis, which is really interesting. I think that received $2 million in the last federal budget.

These options coming on-line in the future are options that we’re seriously considering for expansion.

@AuManufacturing: On the note of funding, there’ve been a few comments recently, from Badri Younes of NASA and Adam Gilmour of Gilmour Space

Technologies, around more investment being needed from government for the Australian Space Agency agency and other infrastructure. Do you believe more funding is necessary?

William Crowe: Yes I do. I think the government will need to come to the table, and I think they’re becoming aware of that. And I can also say that people in the government agencies that have high exposure to space are really putting their best foot forward to launch new missions. And I think there could be a case for an Australian either space exploration mission, or a real flagship mission in the future. So I think that might be one for people to look out for, especially in the manufacturing space.

@AuManufacturing: I think in closing it’d be good to get a sense of your timeline and your goals for the next stages.

William Crowe: Sure. We’re going to have an in-orbit test in Q4 this year. Preferably before, but under-promise and over-deliver, right? And we’ll likely have our first bird in space next year. We don’t have a set date for that yet.

@AuManufacturing: And how are you getting up there? Because one time we spoke you mentioned there’s currently no real way of getting to high Earth orbit.

William Crowe: We’re not really trying to go to the high Earth orbit for these first missions. What we’ve found, in the last six months since talking to you, is that there is demand in low Earth orbit as well, where most of these nanosatellites are sitting. So one, it’s a great test for us to really demonstrate what we’re doing before we go near more valuable satellites, but two, there’s a real business there as well, which is super-exciting.

(Pictures supplied)

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos