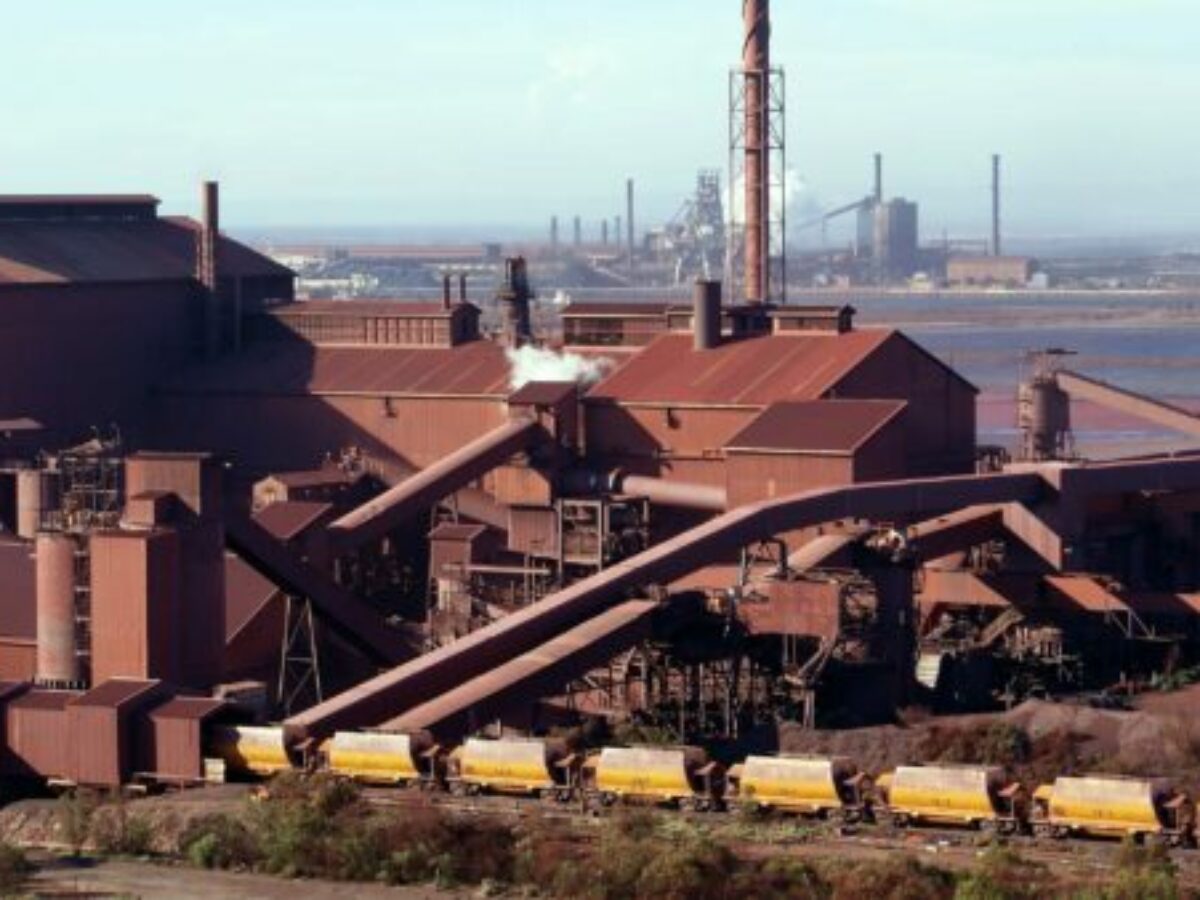

Whyalla site will retire blast furnace, up capacity with new electric arc furnace: GFG

Liberty Steel has announced major upgrades to its Whyalla site, with installation of a new electric arc furnace and associated infrastructure — to replace a blast furnace and coke ovens — expected to be complete in 2025.

In one of two significant announcements on Tuesday involving electric arc steelmaking (see here for Molycop’s polymer injection technology news), Liberty announced that it had signed a contract with supplier Danieli for a 160-tonne electric arc furnace (EAF.)

According to the statement, the investment will see steelmaking capacity at the site rise from 1 million tonnes per annum (mtpa) to more than 1.5.

“Through the steps we’re taking to install state of the art low carbon iron and steelmaking technologies here in Whyalla we will not only support Australia’s climate ambitions, but we will help to decarbonise steel supply chains globally,” said Sanjeev Gupta, Executive Chairman of Liberty's parent company, GFG Alliance.

“Whyalla has some of the best conditions to make low carbon iron and steel anywhere in the world and with our magnetite expansion plans, coupled with South Australia’s endless resource for renewable energy and green hydrogen, the potential for Whyalla has no bounds.”

The new EAF uses Danieli’s Q-One technology, and will initially use domestic steel scrap and other iron-based materials, and make steel with 90 per cent fewer greenhouse gases than regular blast furnaces.

Liberty also said it was engaging international equipment suppliers for a 1.8mtpa Direct Reduction Plant (DRP) in Whyalla, for processing local magnetite ore into low carbon iron (DRI). This will use a blend of natural gas and hydrogen and transition to green hydrogen as it scales up, and “serve the growing global demand for low carbon DRI”.

The federal government linked the news to last week’s passage of the amended Safeguard Mechanism bill through parliament last week, and which will come into effect on July 1.

“This announcement is exactly the kind of investment that industry will make following our safeguard reforms that safeguard our industry, our climate and our economy,” said energy minister Chris Bowen.

Industry minister Ed Husic added that, “This is a tremendous vote of confidence in South Australia’s industrial capability and its capacity to diversify and value-add to locally made products.

“Steel-making and fabrication is an essential part of the Australian economy and will be critical to our plans to rebuild Australia’s domestic industrial base.”

Liberty said its future emission reductions were “aligned with the aims of the Federal Government’s Safeguard Mechanism”.

The new EAF and associated infrastructure would be funded by the business “with an application to be made to the Whyalla Steel Taskforce for a $50 million grant that was committed and funded by the South Australian government in 2016 to be used towards this investment, pending approvals.”

Elsewhere the investment in upgrades to be made by Liberty has been given as “up to $500 million” for the EAF installation and over $1 billion including the direct reduction plant.

Picture: credit www.whyalla.com/steel-works

Further reading

GREENSTEEL EXPANSION PLANS UNDERWAY AT WHYALLA – VIDEO

Topics Manufacturing News Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos