AML3D, Deakin University pursue potentially “revolutionary properties” of BNNT-aluminium wire

Adelaide-headquartered wire arc additive manufacturing company AML3D has announced two feasibility studies with Deakin University — backed by preliminary research and ready to start immediately — investigating the potential of boron nitride nanotubes in aluminium wire.

The company said on Wednesday that the two projects with the university’s Institute for Frontier Materials would explore two new techniques for incorporating BNNTs into aluminium.

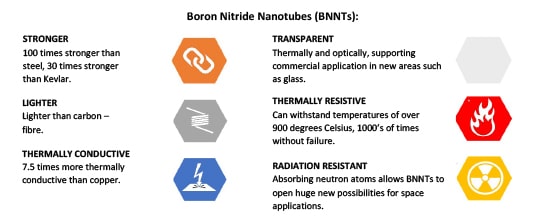

BNNTs are a type of nanofibre with exceptional strength, thermal resistance and other properties (see picture below.) AML3D said it believes a BNNT-aluminium composite “may have revolutionary properties” for the company’s additive manufacturing process.

Picture: AML3D

Founder and managing director Andy Sales said that R&D on alloy development had uncovered potential for the new feedstock.

“I’m extremely encouraged by this new development and hence why we are commencing another two projects separately to our current program,” he said in a statement to the ASX.

“Successful development of these particular alloys has the potential to provide the company with significant upside. The opportunities for products and components has application across all our target sectors and has the potential to add another game changing opportunity for us here at AML3D.”

Sales’s company recently announced joint development on aluminium-scandium wire feedstock with IFM researchers, with support from an Innovative Manufacturing CRC grant.

AML3D is a developer of 3D printing machines and software based on its patented Wire Additive Manufacturing technique — which combines arc welding and robotic control — which allows large-format, near-net shape parts to be built up in consecutive layers. It sells machines as well as its services as a printing bureau.

The news follows the company's announcement this week that it had successfully printed the world’s largest verified oil and gas piping component, a 940-kilogram piping spool tested to the new global API 20S Standard, independently witnessed and verified by Lloyds Register.

Picture: ABB

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos