Catalyst-coated 3D printed alloys could beat the heat for hypersonics

Research from RMIT’s Centre for Advanced Materials and Industrial Chemistry could pave the way for new 3D printed heat exchangers with usefulness in hypersonic vehicles, air purification and elsewhere. We spoke to PhD researcher Roxanne Hubesch about her team’s breakthrough.

The promise of hypersonic flight is an exciting one, but the unanswered scientific and engineering questions to enable it are not trivial.

One of the big ones is managing extreme temperatures. According to one researcher, the air friction for an object travelling at Mach 5 (the speed at which supersonic becomes supersonic) will see leading edge surface temperatures reach 1,000 degrees Celsius.

For a long time, ways of using fuels as a coolant have been investigated to control the buildup of heat in engines.

Research on “Endothermic” (heat absorbing) reactions as fuels are cracked go back to the 1960s, as RMIT PhD researcher Roxanne Hubesch tells us.

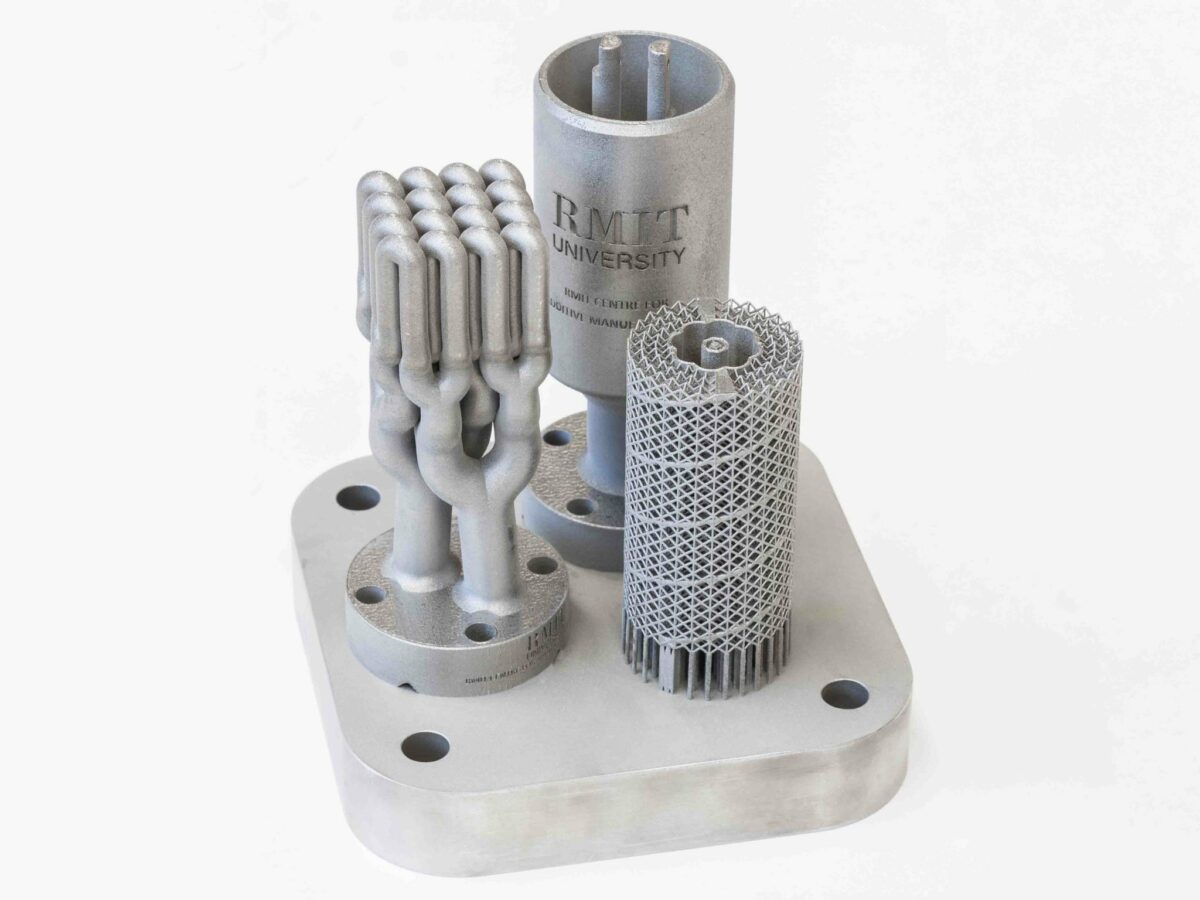

Hubesch was first author on a paper published this month on a new approach, using zeolite catalyst coatings on 3D printed heat exchangers. This used zeolites on inconel lattices to help manage temperatures as hydrocarbons are broken into smaller molecules, with promising early results.

We spoke to Hubesch about the unexpected findings, published in Chemical Communications, and the emerging field combining catalysts with 3D printed structures.

@AuManufacturing: What is the background to this research?

Roxanne Hubesch: I will present myself quickly. I’m from Belgium where I did my bachelor’s and master’s in chemistry. And then I moved to Australia to do my PhDin applied chemistry.

I already had done previous work in catalytic cracking in different applications in Belgium, but it’s basically the same type of chemical reactions. The lab here already did some research in hydrocarbon chemistry, and this is how I got into the field of catalytic cracking for hypersonic flight applications.

When I joined RMIT, there had been a different project going on requiring to build a reactor. I felt that this would be a good opportunity for me to use the same reactor for my PhD project, in order to replicate the same conditions as hypersonic planes, which require shigh pressure and high temperature. The typical conditions in which you have to work are in the range of 40 bar and 500 degrees C. You need special equipment for that. So I felt that if we have these capabilities here, then it means I could work in that field. So I started to build the reactor. Suresh Bhargava, who is my senior supervisor, and also the director of CAMIC (Centre for Advanced Materials and Industrial Chemistry.) had already worked in collaboration with Milan Brandt, who directs the AMP, and has expertise in 3D printing. Suresh and Milan came up around eight years ago with the idea of combining additive manufacturing and chemical science. They published a review on additive manufacturing and chemical science in 2017 which was declared hot topic. Soalong the way, I just felt why not apply 3D printed supports but in the framework of my work? And that’s basically how I got into it. It’s different directions and collaborations which led me there. Initially, in the framework of my PhD work I was only working with pure catalysts, and then we decided to coat some catalysts that I previously studied onto 3D printed supports and we realised that we actually got amazing catalytic conversion. Amazing results, amazing cooling, which we didn’t suspect at all. That’s why we published the work as a Communication, which is not the typical scientific research article. It’s a shorter article which you publish when you have outstanding results and you need quick publication; when your results need to be fast-tracked you usually use Communications.

Picture: Lockheed Martin

@AuManufacturing: The wording in the abstract suggested the result was most likely due to chromium transferring into the catalyst but you were not exactly sure.

Roxanne Hubesch: Yes. We ruled out a few metals and a few things that we know can’t happen. But we suspect chromium contained in the Inconel alloy used to 3D print the support. We did some characterisation of the surface and we suspect it’s little particles of chromium from the 3D printed support which would have migrated into the catalyst particles. Those two combined would work in synergy to produce hydrogen in great quantities. And because the production of hydrogen is really endothermic, which means it cools down a lot, we could apply it successfully to potential cooling applications. As the next step, we’re now preparing our samples to be sent to Japan to be analysed by some synchrotron techniques which will allow us to understand which metal is where on the surface and what is the cause of this catalyst-3D printed metal support synergy. It’s only the beginning.

@AuManufacturing: So some of it was a happy accident?

Roxanne Hubesch: In a way, it kind of was. Initially We wanted to see, first of all, if we could successfully coat some catalyst on the 3D printed support and if this would change something, we hoped this would be a good application for hypersonic flight. If you want to develop efficient heat exchangers for hypersonic planes, you really need them to be compact. The volume of the heat exchanger is really important, but also its efficiency, because you need to convert a lot of the primary fuel into a good combustible secondary fuel, andalso have a really good cooling effect. So that’s why we decided, ‘let’s give it a try.’ We had no clue about what was going to work or not.

@AuManufacturing: We have been quite interested in hypersonics in Australia, with some defence-supported work in the last few years, some expertise and facilities around Brisbane, and a high-profile startup. Have you seen many enquiries after you published your work?

Roxanne Hubesch: The article came out only [this month]. In terms of the research and scientific community, I would say a lot of people are really amazed by the published results. In terms of applications for aeronautics and space engineering, I think a little less. This article is seen from a chemistry perspective. Aerospace is a 100 per cent engineering field, and here we come with some chemical reactions occurring at the heart of heat exchangers for planes. It can be dealt with in engineering, but in terms of researching the why this works there’s a lot of chemistry background to understand. And I think that in some of those fields, multidisciplinary approaches are sometimes a little bit difficult to tackle. In this regard I haven’t been approached yet.

What we have done is using little 3D printed supports to test in our bench scale reactors, and recreating the same conditions of fuel passing in a heat exchanger in a hypersonic aircraft, but it hasn’t been scaled up yet. Our 3D printed supports are only a few centimetres in size.

The next step would also be to try different fuels, because we have used a surrogate fuel that we use in our labs, but this surrogate fuel might maybe not be used in reality. So this is only the first step.

There are also different approaches that have been studied in the field of cooling, not just catalytic cracking of the fuel, and that’s also maybe why people are still a little confused.

Picture: RMIT

@AuManufacturing: I saw that research for hypersonic and supersonic flight using fuel as a coolant, like with the Blackbird, goes back a long way.

Roxanne Hubesch: The first articles using fuels as a cooling agent date indeed from the 60s. But the main issue is the sustainability of the approach. You need your cooling system to be sustainable, it cannot just work for ten minutes. And that’s the issue so far — the cooling approaches we developed technically work, but they only work for a little while. That’s why we also need more work into our system combining 3D printing and catalysts. Maybe carbon deposits from the fuel would happen in a way where it couldn’t run for a long time. There are so many technical issues, and you’d have to combine them in a really clever way. I think that’s why 50 or 60 years down the road there’s still no real application of hypersonic planes. There are so many issues to tackle, and they have to be dealt with together to overcome them and make sustainable hypersonic aircraft a reality.

@AuManufacturing: And there are so many things that can only be modelled and understood up to a certain point and then it’s guesswork. Or so I’ve heard.

Roxanne Hubesch: It’s true. I’ve done two years of chemical engineering research in Belgium before coming here. By working with engineers, I realised the way they think is they like to apply models and trends and functions to a lot of numbers or set of experimental data. But sometimes what is behind the numbers is way more complex and there’s way more things going on than what we expect. Sometimes the research is also still relatively limited in some fields where maybe some phenomenon might happen that we’re not aware of or that we cannot model properly, which means we cannot predict properly. There’s so many different details and approaches that it is still really tricky to develop. We hope that our approach will at least help in the right direction.

Though I have two years of chemical engineering in my background, I’m not an engineer. My expertise and my interest is really to understand what is happening between the catalyst and the 3D printed support. We could upscale this to bigger supports, make bigger reactors to test it, for example, but at the end of the day my real interest was understanding the mechanism behind this catalyst-3D printed support synergy and its amazing catalytic conversion. I would say if we want to scale this and test it further in terms of hypersonic flight applications, then we would really have to work with some aerospace engineering labs to test and understand the different parameters and conditions that they need for their modelling. I guess that’s the best I can say.

We also think that this work could have other applications. We’re thinking about air purifying, for example, or any industry that requires cooling. It wouldn’t just be hypersonic planes. I know the article released by the university is very much about hypersonic planes, but it could be broadened to other things.

@AuManufacturing: Is combining 3D printing with catalysts a fast-moving field with a lot of potential?

Roxanne Hubesch: It’s definitely a hot topic. There was recently a review published in one of the biggest journals in chemical science about additive manufacturing applied tocatalysis. It’s a relatively new field, I would say maybe in the last five to ten years is when you have seen the first articles emerge. But the few articles in the literature for the moment are just 3D printed supports used as such. They haven’t been modified. We are the first to actually deposit catalysts and try it like this.

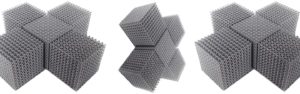

I think that 3D printed supports for catalysts could be a really good application. In the framework of hypersonic planes, they would be really important because heat exchangers need to be really small and using conventional manufacturing to make them would be an issue for that. So in this regard, 3D printing is kind of needed. But I feel like for a lot of different applications where you need really small scale and really defined geometries, this would also be useful. 3D printing also is also interesting in terms of catalysis as 3D printing can produce a really rough surface, which for catalysis is really important because it means that you increase your surface area, and the textural properties are also different to conventional supports.

We could really apply this to so many different fields. In cooling, but we are also thinking of air purifying devices, or using photocatalysis with polymer printed materials. Now we know it works, we may as well try this for many other applications.

(This interview has been lightly edited for clarity.)

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos