RMIT team turns polypropylene waste into fuel and carbon nanotubes

A new two-step recycling method from RMIT University researchers has shown a way to create low-value plastics into higher-value carbon nanotubes and a “contaminant-free fuel”.

The new upcycling approach, outlined in the journal Journal of Environmental Management involves processing organic or agricultural waste into biochar, and then using this as a catalyst for processing plastic. The upcycling used a “fluidised bed” reactor.

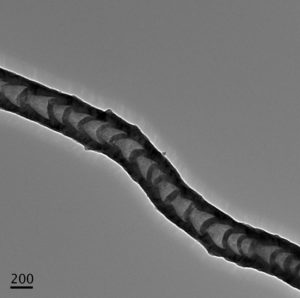

A carbon nanotube (supplied)

Polypropylene, widely used in packaging, was investigated as a feedstock, but the method could be applied to other plastic types.

The approach was tested at the laboratory scale, but the paper’s lead researcher, Associate Professor Kalpit Shah, said it was cost-effective and scalable, and dealt with two high-volume waste streams at once.

The biochar removed toxins from plastic that broke down into fuel, while carbon from the plastic became carbon nanotubes — a high-value nanomaterial with a large range of end uses from medical imaging to strengthening other materials, such as concrete — which coated the biochar.

“We hope this technology could be used in future by local councils and municipal governments to help turn this waste into genuine revenue streams,” Shah said in a statement.

“With Australia banning export of waste plastic from next year, it’s vital that we explore sustainable and cost-efficient alternatives beyond recycling.

“Upcycling plastic with home-grown tech would enable us to draw the greatest possible value out of our limited resources and bring us closer towards a true circular economy.”

According to a federal Recycling market situation review, Australia recycled only 9.4 per cent of its plastic in 2017/18.

A national mixed waste plastic export ban came into effect on July 1, and a single-resin ban will be in effect July, 2022.

The news follows the official launch of Woolworths-backed startup Samsara last week, which is commercialising an enzyme-based, “carbon-neutral, environmentally friendly” way to process plastics into reusable chemical building blocks. Its initial focus is on PET and polyester.

The RMIT team's paper can be accessed here.

Featured picture: texile-plastic-materials-recycling.com/polypropylene.php

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos