A hydrogen hero? Star Scientific to hire 30 next year as it commercialises award-winning Australian breakthrough

Star Scientific is receiving international interest for its hydrogen-fuelled power generation technology, and plans to move into production next year. Brent Balinski spoke to founder Andrew Horvath about what comes next.

Last week an Australian company seemed to emerge from nowhere to claim a long-running international award in energy technology, beating a reported 300 entries from 36 companies.

Star Scientific is not some recently-formed university spinout, and has been investigating clean energy for more than two decades.

The win announced last week in S&P Global’s Platts Global Energy Awards (Emerging Technology of the Year category) was for its recent HERO invention.

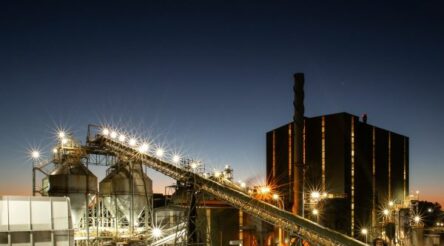

It describes HERO as using a “secret, reusable catalyst” which is not spent up during a reaction where it is in contact with oxygen and hydrogen. According to the company, the results of the “excitement energy” produced are just heat — lots of it, quickly, and in a way that’s ideal for power generation — and water. It says its solution can be retrofitted to existing coal-fired power stations, and could do so at Erarang, for example, consuming around 200 tonnes of hydrogen per day as it replaces coal.

The breakthrough behind HERO (hydrogen energy release optimiser) was discovered by accident only three years ago, and Star says it is already drawing international attention, including an invitation to collaborate on a Department of Energy project in the United States.

@AuManufacturing spoke to the company’s founder and Group Global Chairman, Andrew Horvath, about the HERO story so far, and plans to scale up and open a new site for production next year.

@AuManufacturing: What’s your personal background?

Andrew Horvath: Way back was very young, my father was a nuclear physicist and he was working toward fusion in the 70s, looking at muon-catalysed fusion. So I became very enamoured with all of that. And that’s all I really heard from the day I was born. Working through, I learnt quite a bit about manufacturing, about machining, sciences, but I actually pursued politics and economics. I was in the back rooms of politics for a fair while and I came into the company when I was fairly young for the purpose of really re-engineering the company from a science lab into a corporation. And that became a global corporation. Then I reformed the corporation in ‘97 into Star Scientific and I was its first chairman — still am as well as CEO — and it’s progressed ever since.

@AuManufacturing: What’s happened since getting started, and what projects have you been involved in. What has sustained the company?

Andrew Horvath: Star is based on a guiding principle that we wanted to utilise fusion and hydrogen originally to take over energy generation and make a zero emission energy world. Because we saw that was coming, even back in ‘97 it was fairly obvious.

So we were working toward that. We have a group of very philanthropic shareholders, mostly the larger ones are from the energy world, or have inherited energy money and want to pay back a bit. A lot of others are there because they simply believe in what we believe in. So we’ve been sustained by shareholder funds, probably just over $100 million invested into the company at this point

We’ve been going along doing that. We’ve been doing that research. Then about three years ago in the materials research labs, we had a little issue with the fusion reactor where we would see a strange effect. And we always thought it was electrical. And I said, look, ‘we’ve got to pinpoint this.’ So we put a young scientist on it. Said ‘let’s set it up, let’s put every nuclear instrument we’ve got on it. Let’s create a special box for the thing, use one target out of the system and just keep playing until it does it.’ And then we saw it do it. We thought, ‘well, that’s interesting. We’ve produced a hell of a lot of heat and water.’ And we thought, ‘let’s look into it.’ We used a lot of very high-tech gear, electron microscopes and all those sorts of things. So we really looked into it. ‘Can we do it again?’ And we could do it again, and put a six month program together. Within three weeks, we had not only worked out how to do it, we could do it at will.

And everyone said, ‘well, that’s great. Now we know how to do it. Let’s find a way to stop it.’ And I said, ‘actually, no, if we have a way not using nuclear in any way to make mass heat really quickly — we can go zero to eight hundred degrees in three minutes with hydrogen — then that is a usable heat source for industry power, desalination, all sorts of things.

I put the team onto that and said, ‘look, let’s just focus on this for a minute and let’s see if we can make it bigger.’ The first thing we looked at was because the catalyst, clearly, someone else must have seen this. Went to every science journal, couldn’t find anything, went to our patent attorneys. A month later they came back and said there’s nothing even remotely close to this.

We patented it around the world. And in the meantime, we’re running systems that are putting out megapascals of steam pressure, all the right temperatures to spin turbines. And we’re now building up to mass manufacture. It’s been an interesting journey, and really it’s been sustained by the shareholders.

@AuManufacturing: What work have you done in scaling up the process in the three years and what you’re working with now? A mini-turbine on a lab bench or something bigger?

“So there’s teams of people. The next level, obviously, separate from that, is a separate manufacturing facility, which will be quite sizable. We’re in negotiation with the government looking for the type of land we need,” – Andrew Horvath.

Andrew Horvath: Well, you don’t need to spin a turbine for a start. You can get, you know, ample steam gauges that will give you all the energy and the steam you need. And that’s how the power engineers work.

Basically put out the steam and they go, ‘yep, that will spin this series of turbines.; We do actually have a 1.5 meg turbine in-house if we didn’t want to go that far. But at the moment, we just we’re looking at a range of things that we have to do with this and are breaking into teams at the moment.

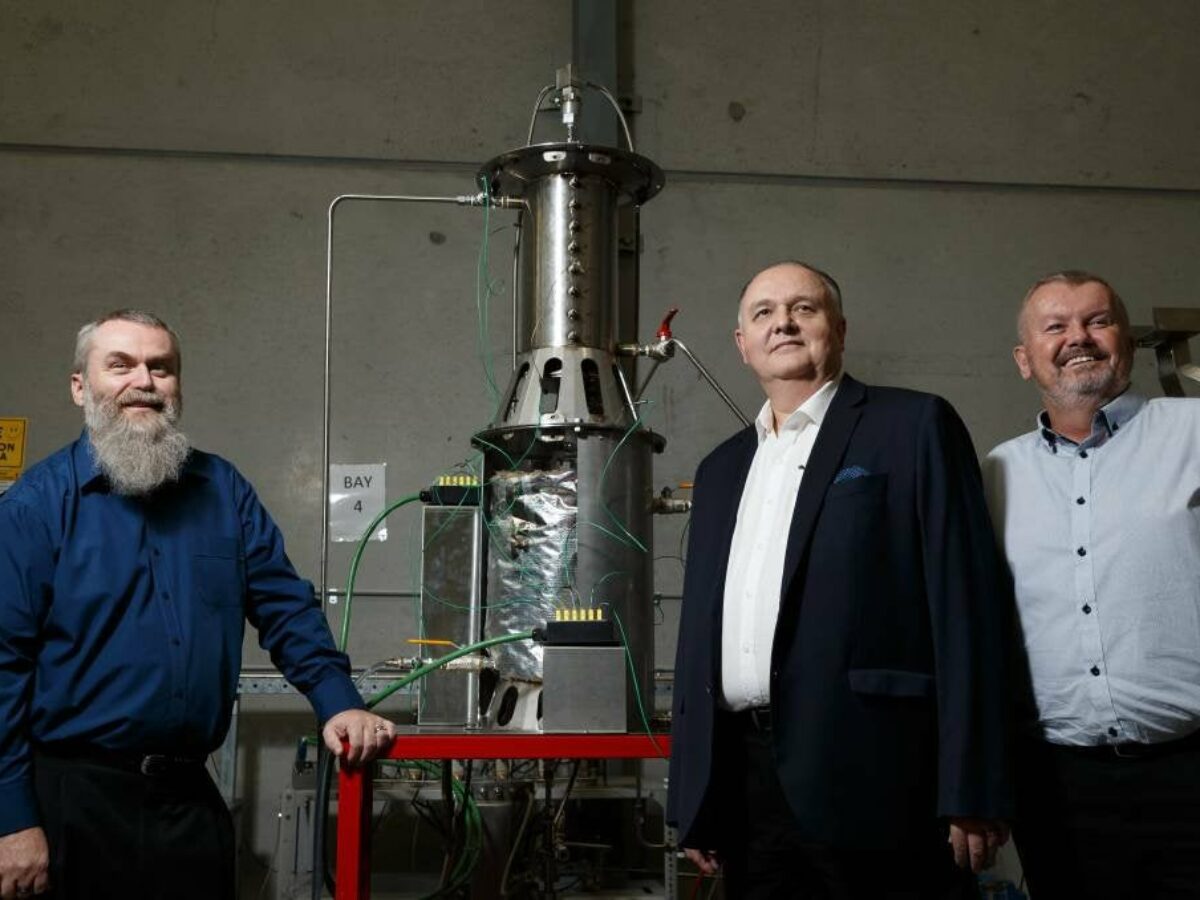

We have a model called 2.5. And that at the moment is a smaller experimental model, probably over 100 sensors on it, all AI-driven, telling us what’s going on inside. It’s effectively catalysing hydrogen and oxygen into water and using that heat through conduction, through a substrate, directly into the material you want to heat. So that could be water, gas, whatever you want to heat. It really makes no difference.

The units we’re running at the moment are about to be upscaled dramatically into the pre- manufacture model, and that’s the first half of 2021. The mode for this will be — think of it as a large cartridge and that cartridge will then add up. So if you want 300 megawatts, you put X number of cartridges together. We’re not selling these units. We’re selling the heat. It’s a heat as a service model, and the units will always be ours.

We’re now running through all the necessary things we need to do. Moving up the amount of hydrogen storage we have on site. We have an 8,500 square metre facility for HERO alone. We do all our own internal manufacturing, probably about 98 per cent of everything that we have we make. There are some things you need from outside.

It’s now progressing to the point of that pre-manufacture stage. We are now looking for land in the Hunter for the manufacturing facility, for HERO in Asia and Australia. We are also looking in Germany at the moment. We’re negotiating with a couple of state governments there in relation to the European manufacturing site. We haven’t crossed America yet, but we’re looking.

So there’s a number of manufacturing sites that will roll out HERO. The first objective is to flip existing coal-fired power stations. When you do that, you exit the coal front, you exit the pollution at the rear, about 52 per cent of the plant disappears. They also save a huge amount of money per year, not having to deal with all that stuff.

And with parasitic energies — for 2.5 gig power station, it’s about 190 meg that they get back in parasitic energy on top. So they become zero emission. long-lived, they can use their turbines or refurbish the turbines if they want. But effectively it becomes a HERO heat exchanger, the water supply, cooling systems, turbine and gen set, and that’s the rest of it all goes away.

It completely alters the way people look at it at the moment where you have to dismantle all these power stations. If we want to tackle climate change and all these other issues, the way to do it is stable power from a spinning mess. It’s not solar and wind: it never was. Solar and wind has to be used to make hydrogen. The smartest way is to use it as a chemical battery. It can be moved around: hydrogen is way quicker through pipes than natural gas. It needs to be stored in farms or hydrogen banks, as we call them. So that’s the general direction we’re heading.

The next step is to work with supercritical CO2 turbines. All supercritical CO2 is 3000 PSI of pressure and 700 degrees of temperature. It acts like a fluid instead of a gas and it holds a huge amount of energy.

That would allow you to decentralise power, put it into nodes. For example, if Penrith’s hot but the rest of the area isn’t, well then you wind up the node in Penrith. You don’t have to wind up Erarang because they need air conditioning in Penrith. It’s a better, smarter way to use power, but it also gives you frequency stable power because you’re running a spinning mass

That’s the direction we’re going. We’re about to become part of a US DOE program to look at attaching HERO to it. They’re doing all the grunt work on the CO2 and they’ve got a number of models in testing at the moment of varying sizes. Our job is to make that zero emission instead of being run on gas.

@AuManufacturing: Is the Department of Energy work a recent development?

Andrew Horvath: It’s just beginning. They’re checking out one last thing in relation rules around which country they can work. Of course they can work with Australia and do already, but have to go through all the checkpoints. I think early in early-January sometime they will come back and it’ll all be OK.

The way it works is effectively say, ‘look, we can tell you this bit, this is how much heat you need. This is how much pressure is going through the system. This is the CO2 loop. This is all the bits we need.’

And we create that loop in our plant and go, ‘right. when we can when we can show you that we can do the exact same thing your gas heaters are doing, let’s get together and put one together and use it.’.

And we create that loop in our plant and go, ‘right. when we can when we can show you that we can do the exact same thing your gas heaters are doing, let’s get together and put one together and use it.’.

Star Scientific has a number of subsidiaries, Planet Power Systems will be the roll out and maintenance company. That company will look at how it’s going to interconnect.

So already we’ve had a lot of discussions with Asian nations. Governments are talking about going to zero emissions in the future. And none of them obviously wanted to stick with steam: they want to go with the most modern way. But they want to go with nodes because they realised that it’s really a smart grid approach that you have to have, otherwise it doesn’t work.

The other big advantage is taking people like the Tomago aluminium smelter, for example, taking them behind the meter. So you take them out of the grid and it just stabilises everything, and also allows you to move those sites where the people are. One of the big issues is where the power comes in is where these places tend to have to go, and they all crowd around the same area and they all tax the same area.

If you grab those big industries and say, ‘look, we’ve got a big population and a new area that could be a new town, that could be bolstered by your industry, we’ll subsidise you to go out there. But you’re behind the meter. You’ve got your own power.’

These sorts of turbines allow for that. And HERO allows for the zero emission aspect of it.

@AuManufacturing: What’s the size of your team?

Andrew Horvath: We’re about to hire about 30 people in the new year. We’ve got 25 people on staff there at the moment. Probably five of those won’t be engineers or scientists. But it’s mainly science-driven. We’re just ordered about $5 million worth of science kit that we need to to scale up our capabilities even further, modernise them even further. Giving us a far better idea of what we have to deal with in terms of managing different aspects of HERO. We know it works, it’s just how it fits into what it needs to do: desalination, for example, district heating, those sorts of things.

So there’s teams of people. The next level, obviously, separate from that, is a separate manufacturing facility, which will be quite sizable. We’re in negotiation with the government looking for the type of land we need, probably near a rail spur somewhere. Where we can pick these things, take them to the port and ship them to where we need to.

This interview has been lightly edited for clarity. You can find out more about Star Scientific here.

Pictures: all pictures Star Scientific, except for featured picture, showing Star Scientific CTO Steven Heaton, chief engineer Jim Murray, and Horvath (Max Mason-Hubers/Newcastle Herald)

Subscribe to our free @AuManufacturing newsletter here.

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos