Chemistry means low-emission steelmaking alternatives remain a challenge: Bluescope boss

Widespread adoption of breakthrough low-emission steelmaking was a “considerable way off,” the CEO of Bluescope has said.

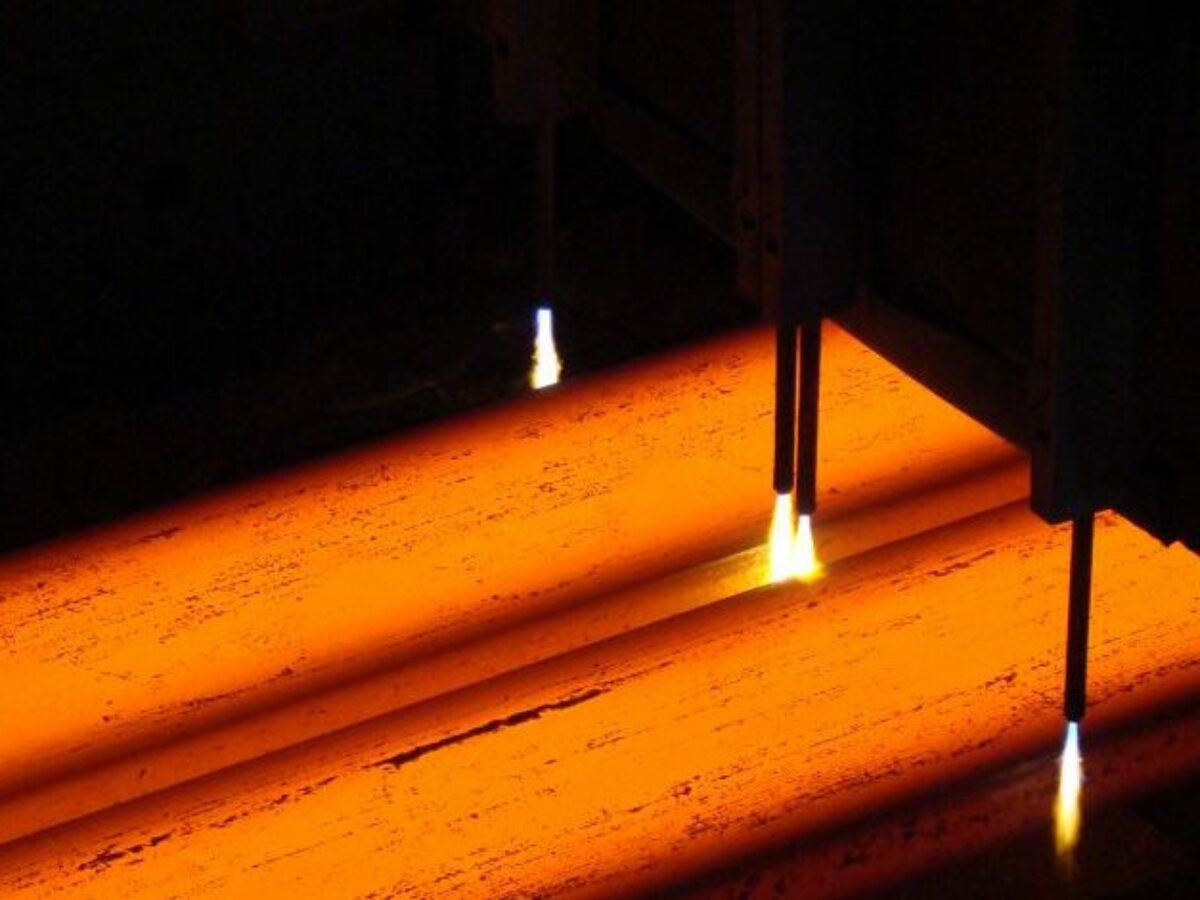

According to The Australian Financial Review, Mark Vasella said the steelmaking industry was striving to reduce its greenhouse gas emissions, and there were alternatives to using fossil fuel-based energy, but the traditional use of carbon required to turn iron ore into iron was hard to replace.

“This means a significant proportion of steel’s carbon footprint is linked to the chemistry of making steel rather than the energy required,” said Vasella.

“Globally, breakthrough low emission steelmaking technologies are in development, but full commercialisation is some considerable way off.”

Possible replacements for coke – used as a reducing agent – include charcoal from biomass and hydrogen, with Sweden’s SSAB leading efforts in the latter method. Elsewhere, the Bill Gates-backed MIT spinout, Boston Metal, is attempting to commercialise a carbon-free “molten oxide electrolysis” method.

Bluescope has a target of reducing its emissions intensity for steelmaking by 1 per cent a year up to 2030. Vasella has previously mentioned that he is skeptical that low-emission steelmaking is near to widespread adoption.

Production of steel currently contributes about 6 per cent of greenhouse emissions. Remelting scrap – which produces about a quarter of the CO2 compared to creating virgin steel per tonne – is one area where progress can be made, said Vasella.

Subscribe to our free @AuManufacturing newsletter here.

Topics Manufacturing News

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos