AML3D awarded $1.54 million contract on copper-nickel alloys for US submarines

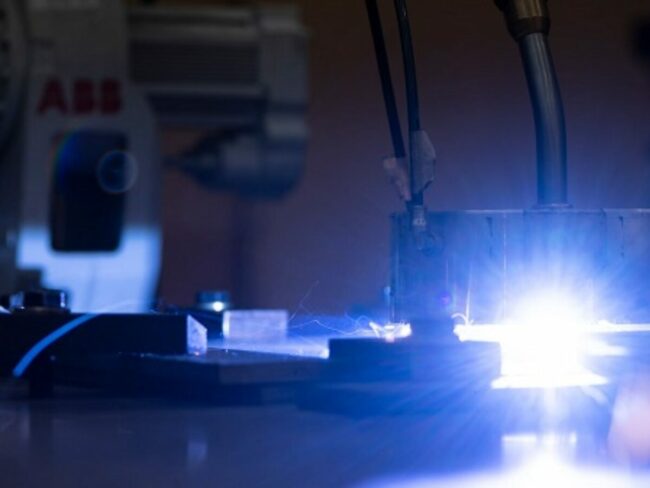

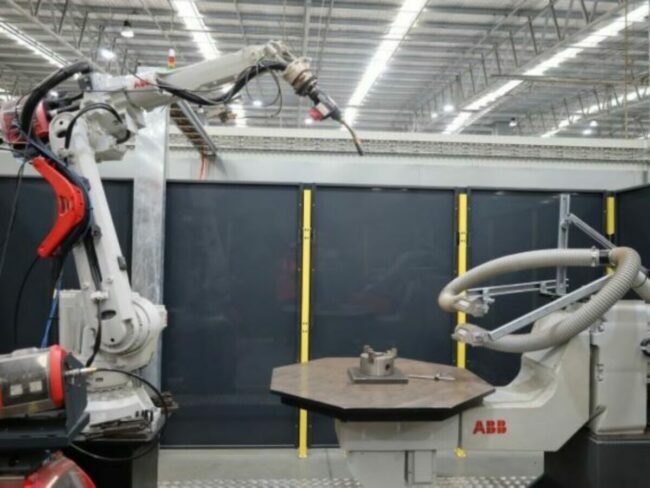

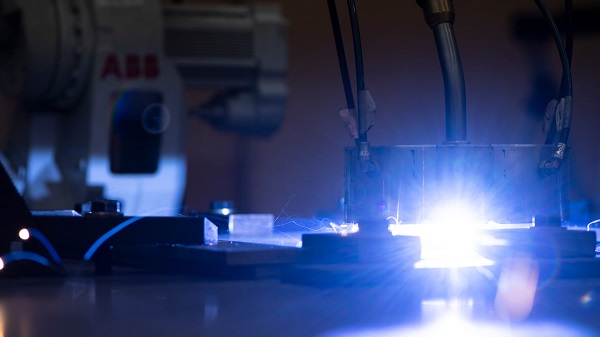

Wire arc additive manufacturing business AML3D has announced receipt of a purchase order worth $US $1.01 million (approximately $1.54 million) to support qualification testing of copper-nickel (Cu-Ni) alloys for US Department of Defense applications. The original contract to develop and test AM Cu-Ni components for the US Navy’s submarine program was announced in September last…