A half-dozen things to watch in 2022

We have an ability to see into the future equal to anyone else’s; in short, non-existent. That said, here is a random handful of issues we predict will be meaningful to the industry in 2022, and which we will therefore be keeping tabs on. By Brent Balinski.

Optimism, with a Covid caveat

Manufacturing ended last year with a lot of very encouraging news and sentiment. According to the quarterly ACCI-Westpac Survey of Industrial Trends out on December 14, manufacturers displayed “a very positive outlook,” with optimism at its highest since 1994, and anticipated “a strong and accelerated recovery in 2022.” Material and labour constraints were troubling, but things were overall in solid shape.

Manufacturers and others were hiring, too. With record job vacancies in the three months to November 30 – nearly 400,000 of them – and 29,500 roles in manufacturing open.

The picture is of course different now, thanks to Omicron.

Given the twists and variants in the pandemic story, it’s hard to say when or how life and business will return to something like normal, but there’s some hope. Last week The Australian Financial Review featured a set of local business leaders commenting on the current wave. Among them, CSL’s Brian McNamee expressed positivity, citing high local levels of vaccination, data related to the peak and decline for cases in the UK, and the shift from pandemic to endemic, commenting, “in essence, I think we’re heading towards a phase of normalising our lives – thank goodness.”

Manufacturing grew in employment (topping 1 million jobs) and in its appreciation last year, and if the disruptions pass, it should strengthen further.

Manufacturing matters – and we’ll continue hearing about it

According to research published by the Advanced Manufacturing Growth Centre last year, more and more Australians are valuing the industry, and 72 per cent of Australians see it as important or very important, up 7 per cent between 2019 and 2021.

As supply chain disruptions did in 2020, the current ones are a reminder of how desirable it would be if we could make and use certain things for ourselves (for example rapid antigen tests.) We predict manufacturing and its role in sovereignty will be a 2022 election issue, with the investment in the industry by the federal government and the effectiveness of this and other industry policies certain to be debated.

On the media front (and this is anecdote-based) there also appears to have been a shift in coverage in the last two years. As one example, early this month the ABC reported on the growth at some companies over that period and the hopes of a post-Covid boom in manufacturing. A comment from that story by Sevaan Group co-founder Jim Tzakos is reproduced below:

“Covid’s been a blessing for manufacturing in Australia, ‘cause it’s opened people’s minds, and suddenly… supply chains that couldn’t get product from overseas are now having product made in Australia. Some of them have seen that there’s not that much of a cost difference.”

The fact that Australian companies can and do manufacture competitively, and that they should be supported, is an important message and one that needs to be spread.

Policies and programs

Pre-Christmas, there was news the Growth Centres would be given another $19 million to help them transition into self-sustaining operations.

But after that, what will be the major federal programs promoting transformative industry-research collaborations and commercialise new products, processes and services?

The results of a CRC round are scheduled to be released in May, with candidates including bids from a CRC for Intelligent Manufacturing (CRC4IM), Sovereign Manufacturing Automation for Composites (SoMAC) CRC and Plastic Waste CRC. These could answer the question.

The Growth Centres, which Labor wanted to abolish at the 2019 election, have been repositioned by the opposition as “a successful program where the decisions get made by industry” and something the government wants to kill off to regain control of grant distribution.

Differences over these plans and Labor’s – which include a $15 billion National Reconstruction Fund loan scheme compared to the Clean Energy Finance Corporation – will feature in the run-up to the election, which must be held on May 21 or sooner, and must feature a campaign of at least five weeks’ length.

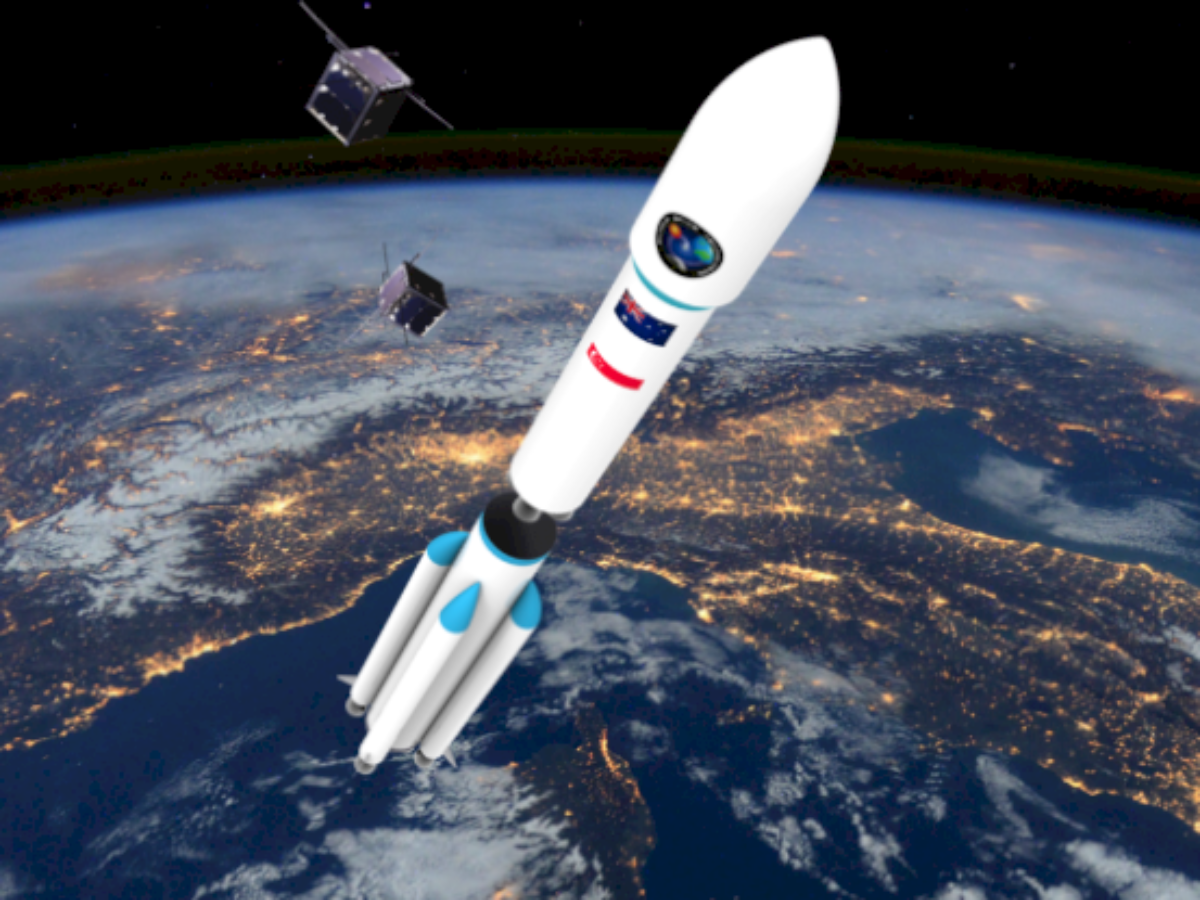

Australian commercial space launches take off

If it’s successful, one of the history-making achievements of the year will be Gilmour Space Technologies’ planned launch in the second half.

The Gold Coast rocket manufacturer and launch provider began the year with an engine test fire running 75 seconds and generating 110 kilonewtons thrust. According to Gilmour, they would put the final touches on their Australian designed and made Eris rocket (pictured) between March and June, with blast-off sometime before year’s end.

Australian passengers include Space Machines Company, Spiral Blue, Esper Satellite Imagery, Sperospace and Dandelions.

The return of expos (with a Covid caveat)

The year also holds the promise of a return to expos, following the reschedulings and then demise of National Manufacturing Week in 2020, and reschedulings of its replacement – AMTIL’s Australian Manufacturing Week.

AMW is set to run June 7 – 10 at Darling Harbour’s International Convention Centre.

This year will also see the debut of a Modern Manufacturing Expo, with this planned for September 20 – 21 and a launch event/Town Hall on February 16.

After two years without a major face-to-face industry show, we are looking forward to both events. Fingers crossed…

A sea of opportunity

Developing technologies to help humanity decarbonise is a real opportunity here and elsewhere. From the electric vehicle industry to solar energy solutions, there are local success stories – such as Tritium and 5B – with giant international possibilities ahead of them.

There are other acknowledged opportunities in zero-emissions or emissions-lowering solutions, such as hydrogen energy, bioenergy and various kinds of recycling.

One place we’ll be looking is the sea. Here are some reasons why.

The methane-reducing abilities of a seaweed native to Australia and New Zealand has been investigated by CSIRO and James Cook researchers for years. A compound in asparagopsis acts on gut enzymes in the last stomach of cows, with small amounts almost eliminating production of methane (a potent greenhouse gas, and released as burps and farts) when consumed by the beasts. According to one estimate, the planet’s 1.5 billion cows each contribute about 100 kilograms of methane a year.

CH4 and Sea Forest are two companies leading the way in trying to produce feed additives for cows at large scale using asparagopsis extract, which also has benefits to animal growth and productivity. According to the Australian Seaweed Institute, asparagopsis could represent a $100 million market by 2025 and $1.5 billion by 2040.

Last year Sea Forest, which aims to be “first in the world to cultivate Asparagopsis at a commercial scale” raised $34 million through an oversubscribed funding round. It plans 7,000 tonnes per year from its stage 1 farm in Tasmania, which it says is enough to supplement the diets of 150,000 cattle and decrease emissions by 400,000 tonnes per annum.

Seaweed in various forms can be used in food and pharmaceutical products, as well as plastics and fuels. It also grows much faster than land-based plants, therefore sequestering more carbon dioxide through photosynthesis. The challenges, point out critics, are in doing things economically and – a related problem – at the necessary scale.

Scale in harvesting and processing is what will be needed, say those who acknowledge the potential for aquatic plants to undo greenhouse gas pollution.

In September last year we spoke to Jefferson Harcourt, founder of commercialisation specialist Grey Innovation. He described a venture being considered, combining seaweed forest cultivation off oil rigs, hotels, and seaweed-derived biodiesel.

“Seaweed is the next big thing. It’s a civil engineering exercise – that’s how we’re looking at it. We need to grow this stuff at scale,” he told @AuManufacturing at the time.

“And when you look at the ventures that are existing to date, when you look at seaweed production, it’s very much a cottage industry, manually harvested and so on… We need hundreds of millions of hectares, billions of hectares… stuff that you see from space… When you’ve got that much seaweed, you can really move the dial on taking the carbon and the nitrogen out of the ocean.”

Picture: Gilmour Space Technologies

Subscribe to our free @AuManufacturing newsletter here.

Topics Analysis and Commentary

@aumanufacturing Sections

Analysis and Commentary Awards Defence Manufacturing News Podcast Technology Videos