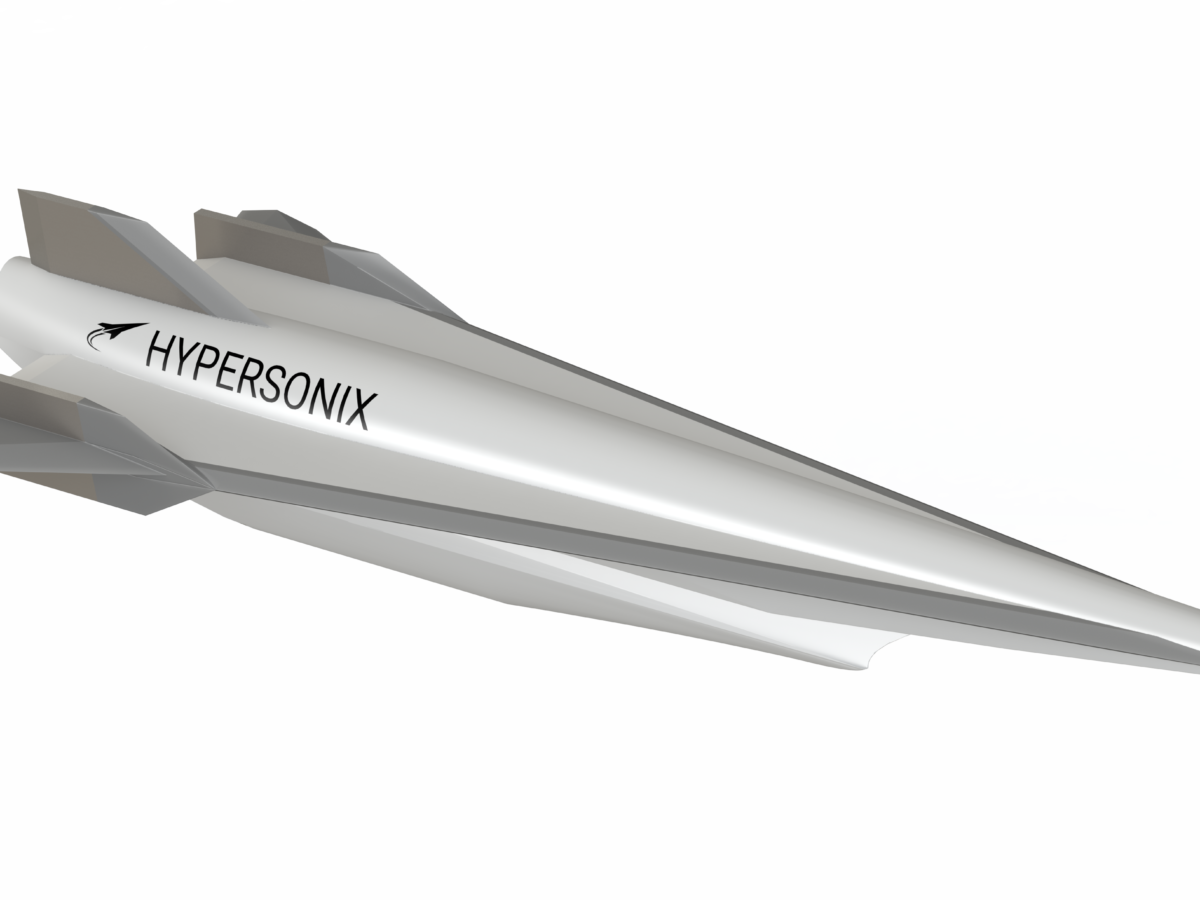

Australian team discusses composite hypersonic UAV project to begin in July

Hypersonix Launch Systems has provided further details about a project that was recently awarded a $2.95 million Cooperative Research Centres Projects grant, and which is scheduled to begin in July.

Last week Hypersonix was announced as lead of a project titled “DART CMP Airframe – a reusable hypersonic platform” that had earned support in Round 12 of the CRC-P program. The team includes Romar Engineering, LSM Advanced Composites, and University of Southern Queensland, and seeks to “deliver a new sovereign manufacturing capability” for a reusable hypersonic craft.

The craft will use a SPARTAN scramjet engine developed by Hypersonix, fuelled by hydrogen, and capable of speeds up to Mach 12, according to the company. Hypersonic speed begins at roughly Mach 5, or five times the speed of sound.

Hypersonix said the project will deliver elements including a UAV (unmanned aerial vehicle, or drone) airframe “including composite aeroshell and aerodynamic control surfaces, flight avionics, and hydrogen fuel system.”

In a statement from the company’s Managing Director, David Waterhouse, he explained that DART CMP will be a composite version of their DART AE, which is under development and due for launch in 2023. AE stood for “additive engineering” and is “the fully 3D printed version out of high temperature alloys that are already available in Australia,” said Waterhouse.

“The type of high temperature composites we require for DART CMP are currently not available here, therefore there is an urgent need to develop these materials in Australia.

“We are thankful that the government acknowledged this gap and responded with accepting our application. We can’t wait to have these materials ready in mid 2025.”

The collaborative project would see the aerospace company – which plans to eventually fly small satellite customers to low earth orbit – support three PhD students in a developing industry that needed more experts, said Michael Smart, Hypersonix’s head of research and its co-founder, and a former Professor and Chair of Hypersonic Propulsion at University of Queensland.

USQ’s Institute for Advanced Engineering and Space Sciences Executive Director, Professor Peter Schubel, said his team would apply its research expertise in hypersonics and future materials to the mission.

“Our role in the project will be to develop and test the prototype ultra-high temperature composite material needed,” said Schubel.

“Our expertise in liquid moulding technologies, automated fibre placement, pultrusion and filament winding capabilities with exotic materials allows us to develop revolutionary structures.

“As an industry-focused research and technology organisation, we are committed to delivering real-world, large-scale solutions for our clients, utilising our extensive laboratories and manufacturing equipment.”

Additive manufacturing would be used where possible, the statement said, with this covered by Romar Engineering with Steve Milanoski, an ex-SpaceX engineer who leads Romar's expanding AM team.

Hypersonix and Romar Engineering – an established contract manufacturer based in southwest Sydney – announced a framework agreement to “collaborate on 3D printing and other manufacturing techniques” last July. That same month Romar was awarded a $5.8 million federal grant to invest in AM machinery and staff to manufacture “space fluid and motion control products.”

“We are very excited to be working with Hypersonix, USQ and LSM on the development of the DART CMP. The project represents a significant leap forward in technology for the fast-growing Australian space industry,” said Romar’s CEO, Alan Lipman.

Picture: supplied

Subscribe to our free @AuManufacturing newsletter here.

Topics Technology

@aumanufacturing Sections

Analysis and Commentary Awards casino reviews Defence Gambling Manufacturing News Online Casino Podcast Technology Videos